Dr.Air KT48000 Industrial Electrostatic Precipitator

430,000,000₫

- Model: Dr.Air KT48000

- Wind flow: 48000m3/h

- Machine dimensions (LxWxH): 1775 x 685 x 2540 mm

- Case: Carbon Steel (Q235A – 2mm).

- Filter dimensions (LxWxH): 360 x 510 x 480 mm

- Number of filters: 12

- Filter membrane plate thickness: 1mm – Aluminum alloy.

- Number of Tungsten threads: 192

- Power: 680W

- Pressure resistance level: 200 pa

- Cleaning rate: 98% or more

Dr.Air KT48000 industrial electrostatic precipitator is designed to handle smoke and remove particulates rigorously and regularly.

The main function of the Dr.Air KT48000 electrostatic air purifier is to filter smoke, grease and odors generated during the cooking process. The machine becomes a powerful tool for smoke and odor control, meets the stringent requirements of air quality and technical regulations of removing grease oil particles from the exhaust gas stream.

The advantage of the KT48000 in particular and the Dr.Air electrostatic precipitators line in general is that it allows the maximum removal of contaminants before discharging kitchen smoke into the natural environment, helping with decreasing fire fighting and cleaning costs. At the same time, it also helps install the system beautifully and scientifically.

Advantages of electrostatic filter have good smoke removal & oil filtration ability with efficiency up to 98%, easy integration into existing exhaust gas treatment system. In addition, electrostatic filtration combined with much other equipment such as Dr.Air AA filter box, Dr.Clean adsorption stamping tower, Dr.Ozone ozone deodorizer machine, … brings thorough treatment performance.

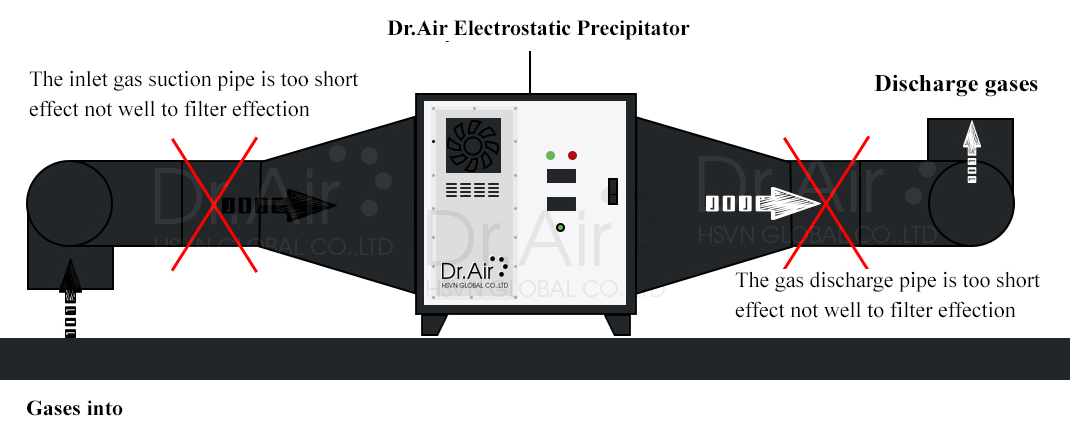

Some notes when installing the electrostatic filter

Avoid installing the length of the inlet and outlet exhaust air pipe too short

The length of the inlet exhaust gas leading pipe needs to be more than 3 times the pipe diameter, the exhaust gas outlet through the electrostatic filter needs to be larger than 2 times the pipe diameter.

The inlet and outlet exhaust gas pipes are connected to other equipment or exhaust fans by flexible connect hoses. In addition, for the best performance of the electrostatic precipitator, it is required that the exhaust fan be installed behind the electrostatic precipitator.

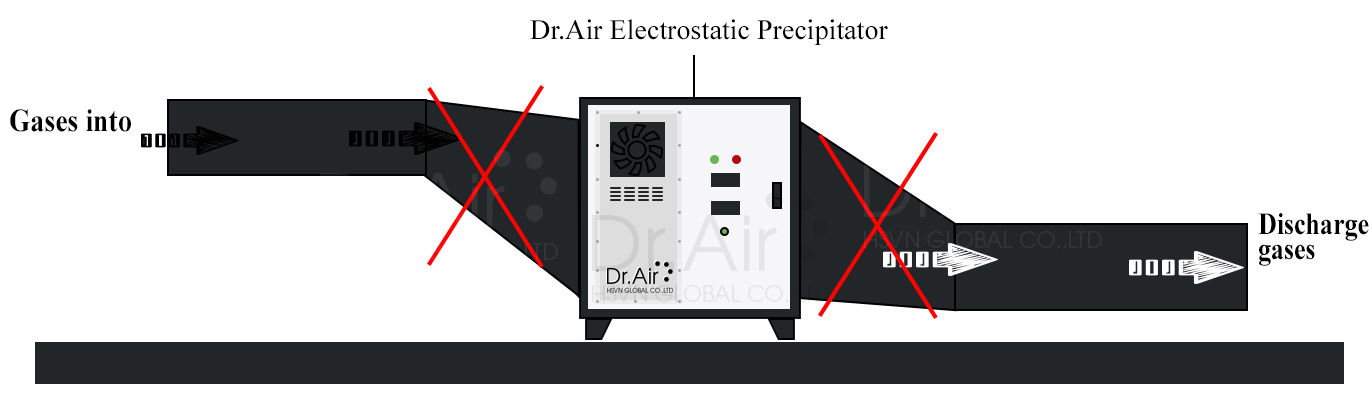

Avoid designing the gases capture suck in the wrong way

The angle of the gases capture suck needs to be tilted at an angle greater than or equal to 60o, balanced, located on a straight line with the center of the electrostatic filter to ensure the best air circulation, evenly distributed through the electrostatic filters, increasing the processing efficiency, offload for the position.

Reviews

There are no reviews yet.