Industries, Aquaculture

Ozone Generator For Aquaculture

Ozone has been proven capable of improving water quality, enhancing the efficiency of the water treatment systems for aquaculture and aquafarming, especially in Recirculating Aquaculture Systems (RAS system).

Bacterial and viral create diseases and serious problems in intensive and semi-intensive aquaculture. Contaminated water can make heavy losses in aquaculture and has also limited the progress in the farming of new aquacultural species. Use of the water sources in systems has a risk of contamination can introduce waterborne aqua species pathogenic microorganisms.

The solution for these problems is to find dependable means to control pathogens present in the inlet water. In which, two ozone disinfection or UV-irradiation methods are often applied in aquaculture.

Ozone generator for aquaculture water treatment

Ozone has widely used in aquaculture and aquafarm because it rapidly reacts, produces few harmful by-products in freshwater. Moreover, oxygen is produced as a reaction system end-product. It is an extremely reactive oxidant, a very effective bactericide and viruscide.

Ozone can also achieve water quality improvements by micro flocculating fine particulate matter, removing organic compounds suspended in water and oxidizing non-biodegradable organic molecules, nitrite…

Fine and colloidal solids removal: Fine and colloidal solids are particles 1-30 microns (mm) and 0.001-1 mm in size. The small size of the particles allows avoiding most mechanical separation methods. The accumulation of the fine and colloidal solids can reduce the nitrification efficiency of the biofilter. Ozone removes fine and colloidal solids by causing clumping of solids (microfiltration), facilitating removal by foam separation, filtration and settling.

Removes dissolved organic compounds: Dissolved organic compounds (DOCs) give water a characteristic color. DOC is non-biodegradable and accumulates follow feed input, water exchange rate and solids removal rate. High levels of DOC can stress fish and reduce the nitrification efficiency of the biofilter. Ozone removes dissolved organics by oxidating them to products that are more susceptible to nitrification in the biofilter; including precipitation, allowing the removal of waste particles by conventional filtration or deposition.

Nitrite Removal: Nitrite can accumulate when strengthen production and organic payloads with increased biofilters. Bacteria process ammonia to nitrite work more efficiently under higher organic payloads than bacteria process nitrite to nitrate and nitrite levels increase accordingly. High levels of nitrite can be toxic to fish. Science data for silver perch indicate that the nitrite level as low as 2.8 parts per million (ppm) can result in a 5% reduction in fingerling growth. Ozone removes nitrite by direct oxidation to nitrate; reduces the organic load, which improves the efficiency of biological filtration and nitrification.

Disinfection: Ozone can effectively neutralize a wide range of bacterial, viral, fungal and protozoan pathogens. The effectiveness of ozone treatment depends on ozone concentration, duration of ozone exposure, pathogen load and organic matter levels. If there is a high organic matter content, the demand created by oxidizing the organic matter can make it difficult to maintain residual ozone for effective disinfection.

Dr.Ozone ozone generator for RAS system

Recirculating aquaculture systems offer more potential advantages than other forms of pond or cage aquaculture. These include flexibility in site selection, reduced water use quantity, lower wastewater output, bring better environmental control and higher production intensity.

However, when water storage and reuse density increase, waste accumulates rapidly make environmental control becomes more difficult. At that time, need the sophisticated systems capable of removing both particulate and dissolved organic waste become necessary.

Conventional dissolved organics removal methods such as filters and clarifiers can remove settleable and coarsely filterable solids, but do not remove colloidal solids. Similarly, bacterial nitrification in a biofilter removes dissolved ammonia and nitrite, but cannot remove other dissolved wastes. When organic matter concentrations increase following production intensity, the microorganisms converting nitrite to nitrate are less efficient, resulting in increased nitrite levels.

The accumulation of colloidal solids, dissolved organic matter and nitrite in the RAS system can impair biofilter function, increase biochemical oxygen demand and stress levels in the culture warehouse. The continued impact of organic waste in the water makes a system less stable, less productive.

Increasing the daily water exchange rate in the RAS system will remove accumulated colloidal solids which are detrimental to water reserves and system heating or cooling costs. The alternative removal method is to decompose these organic wastes by using an oxidizing agent such as ozone. Ozone is also widely used to disinfect water supplies and wastewater for the RAS systems to eliminate pathogens.

|

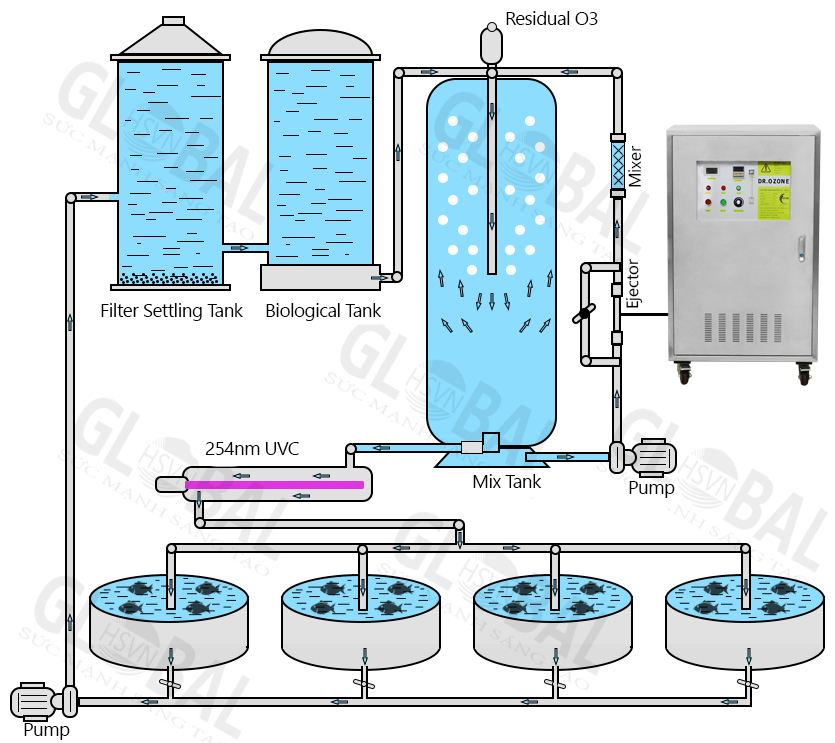

Simulation of the aquaculture water treatment & disinfection system with Ozone: The Dr.Ozone machine supplies purified ozone with a concentration of 80 – 90g/m3 into the RAS circulating water treatment system through Ejector. Ozone is mixed evenly into the water of the Mixer & Tank mixing system, performing the process of sterilization, disinfection, decomposition of the solids, glue, dissolved organic matter. The excess Ozone is taken out of the mixing tank and a part goes through a 254nm UVC wavelength lamp system. The UVC lamp not only converts excess Ozone into Oxygen but also combines Ozone to participate in advanced disinfection by generating Hydroxyl (*OH) free radicals to maintain water quality. |

Dr.Ozone ozone generator for saltwater recirculating aquaculture systems

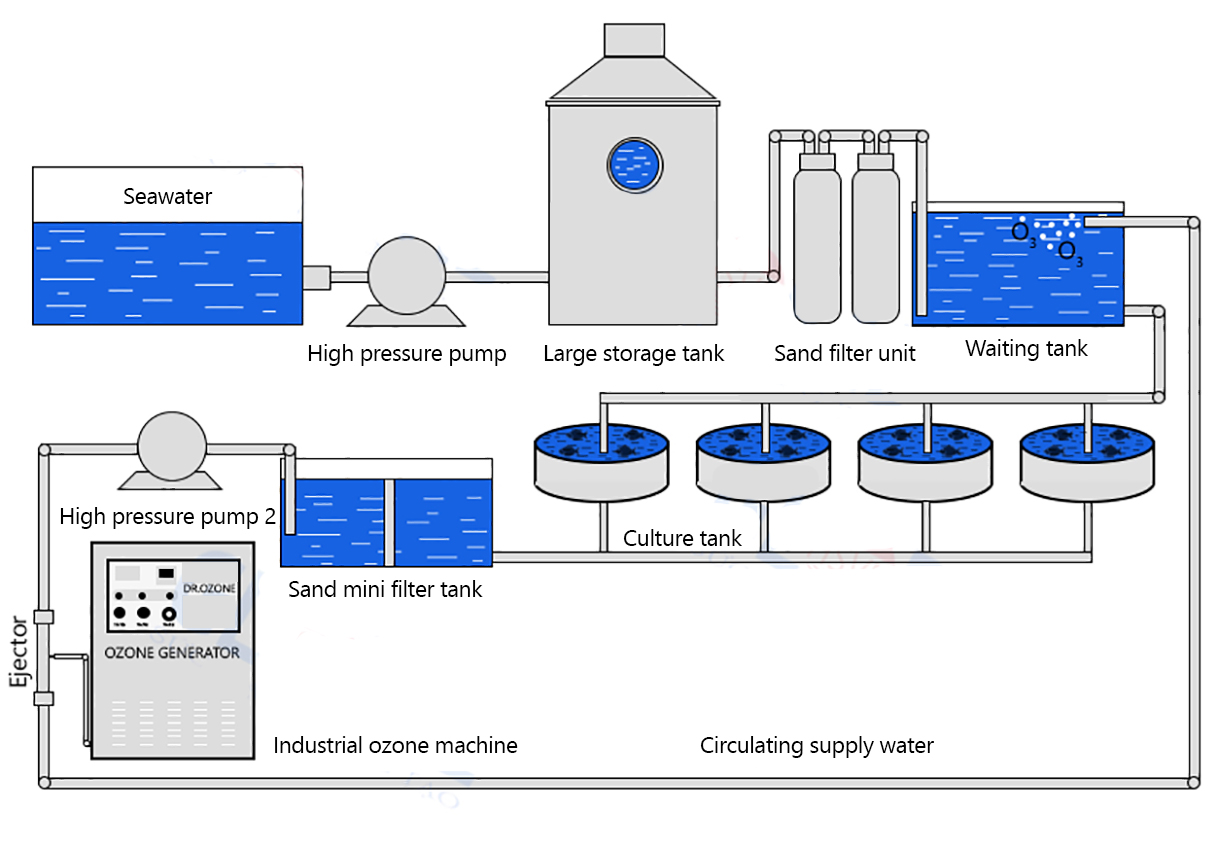

This aquaculture model usually uses the coastal area. The seawater is led into a large chamber through a high-pressure pump and filtered by a sand filter into the tank waiting to supply water for aquaculture.

The saltwater recirculating aquaculture system

In this model, ozone technology is used for recirculating water disinfection & treatment similar to RAS. Ozone is injected into the disinfected water and the treated water leads directly to the waiting tank. The advantage of this system helps farmers better manage water quality, avoiding farmed aquatic species damage if affected by natural seawater.

Use ozone the right dose and the right way to promote the amount of agriculture output

The needed ozone amount to improve water quality is usually calculated as a daily feed rate. An ozone 10-15g rate per kg feed is generally recommended to reduce accumulated organic matter. If disinfection is the primary goal of the zonation process, the amount of required ozone is largely dependent on the organic matter content in the water that needs to be treated.

|

In purified water, residual concentrations of 0.01-0.1 ppm ozone for as short as 15 seconds can be effective in reducing bacterial amounts. |

However, in water where there is still a high concentration of organic matter, the residual ozone concentration and ozone exposure time must be increased for creating comprehensive disinfection.

|

Natural waters (seawater, brackish and freshwater) typically require a residual concentration in the 0.1-0.2 ppm ozone range and a 1-5 minutes contact time for disinfection. Aquaculture wastewater typically requires about 0.2-0.4 ppm of residual ozone for 1-5 minutes for the significant disinfection to occur following organic matter oxidation. |

The optimal ozone ratio for sterilization varies widely and represents for the total ozone demand from dissolved organics, colloidal solids, nitrates, and sterilization. In many situations occur RAS system, the cost of producing residual ozone is sufficient for complete sterilization after all other ozone needs are met. However, decrease some pathogen reduction can be achieved using moderate ozone levels and significant water quality improvements.

Disinfection of source water with ozone, combined with quarantine procedures, reduces the risk of disease outbreaks in the aquaculture system. The solution to integrate Dr.Ozone into the system depends on the water treatment process customers are using.

The two above models are our most comprehensive and ideal aquaculture water treatment models. For the exact solution to bring optimal efficiency, please contact us

You can contact us any time via Chat Box or Hotline for the best advice.

Dr.Ozone Headquarter

Address: No.30, Truong An Industrial Cluster, An Khanh Commune, Hoai Duc Dist, Ha Noi city, Viet Nam

Website: dr-ozone.com

Inbox us: Fanpage Dr-Ozone