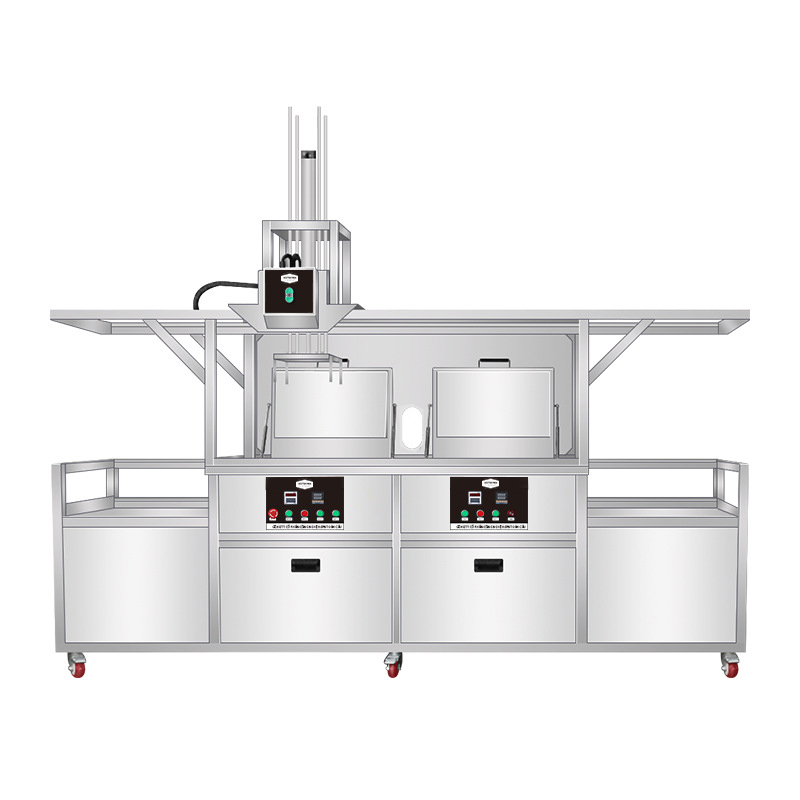

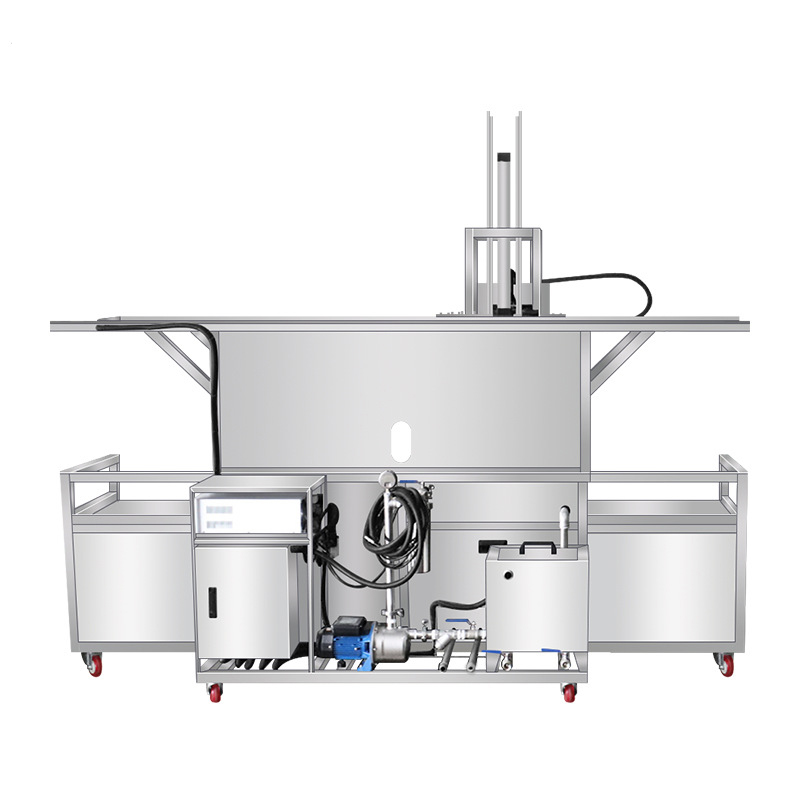

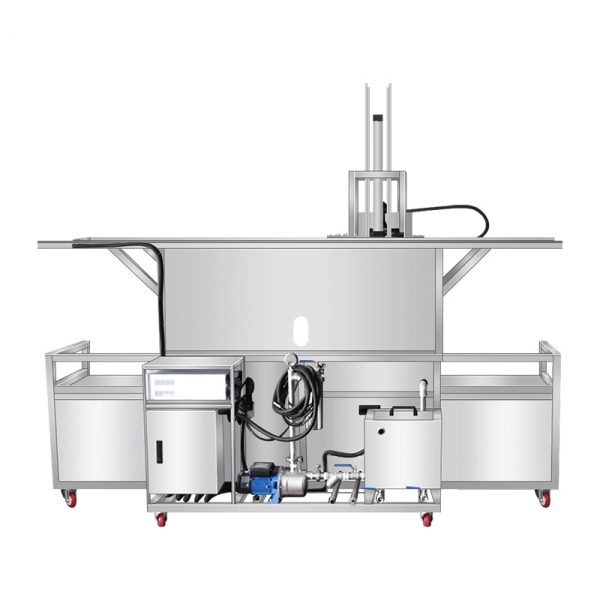

VietSkymen ultrasonic tank cleans helmets

- Brand: Vietskymen

- Frequency: 28-40KHz

- Technology : Ultrasound

- Application: cleaning objects and components in production

- Detailed specifications will be made to order to suit customer needs.

To get a complete helmet must go through many different stages. In which molding the helmet is an indispensable stage. After being molded, the helmet mold will still have a lot of dirt and impurities that need to be removed to ensure that it does not affect the helmet finishing stages later.

Operating principle of ultrasonic cleaning tank

The principle of cleaning Rama ultrasonic technology is based on the oscillation of air bubbles created by the ultrasonic pressure used in mixing liquids. This mixing creates air bubbles, which are continuously formed and broken, creating powerful shock waves that wash away stubborn stains on the surface to be cleaned. Ultrasonic technology is very popular today because it can remove all stains in the corners of the product. Especially for products with many impurities.

To improve the cleaning efficiency of ultrasonic cleaning machines, it is possible to combine them with specialized chemicals and cleaning solvents. The choice of these chemicals depends on the dirt adhering to the surface of the product, which can be dust, grease, rust, bacteria, blood, etc.

Rama ultrasonic cleaning in some cases does not require disassembly of the components before cleaning. The items to be cleaned should not come into direct contact with the tank bottom as this can prevent cavitation from occurring on the surface not in contact with the solution. Therefore, Rama ultrasonic cleaners and ultrasonic cleaning tanks are usually supplied with a dedicated basket.

Advantages of designing a dedicated washing tank for cleaning helmets

Using a multi-purpose cleaning tank for cleaning helmets can be a temporary solution, but to optimize production efficiency and improve product quality, investing in a specialized cleaning tank design is essential. With a design that fits the size and shape of the helmet, the specialized cleaning tank helps ultrasonic waves penetrate every corner, including complex details, ensuring complete removal of dirt, grease, and stubborn dirt.

Furthermore, the arrangement of the ultrasonic probe is carefully calculated, focusing energy on the areas that need cleaning, helping to shorten the processing time for each product. The specialized washing tank can also easily integrate conveyor systems, robots, automate the cleaning process, minimize human intervention, and contribute to improving labor productivity.

In addition to the outstanding cleaning performance, the dedicated tank also brings practical economic benefits. The closed design and optimized solution flow help to minimize the amount of cleaning solution used. Ultrasonic systems operate more effectively in dedicated tanks, thereby saving energy consumption.

In particular, fixing the helmet in a specialized washing tank helps to limit impacts and scratches during the cleaning process, protect the paint layer, and prolong the product’s life. With outstanding advantages, a specialized washing tank is not only a solution to improve production efficiency but also a key factor in affirming the reputation and product quality of the enterprise in the market.

Difficulty in cleaning regular helmets

The processing of motorcycle helmets in the production process, although simple, is fraught with difficulties that require meticulousness and strict control. Right from the time the helmet shell is shaped, removing burrs, raised edges or cleaning mold oil must be done precisely to avoid scratching the surface, affecting the aesthetics and quality of the product.

Before painting, cleaning dirt and treating static electricity is extremely important. Dirt on the surface will cause uneven paint layer, and static electricity will reduce the adhesion of paint. After painting, the helmet needs to be completely dried in appropriate temperature and time conditions to avoid peeling and cracking.

The assembly stage also presents many challenges. Details such as the lining, windshield, buckles, straps, etc. need to be cleaned thoroughly before assembly to ensure hygiene and aesthetics. During the assembly process, great care must be taken to avoid scratching the paint, especially with helmets with a glossy paint finish. Finally, the packaging stage must also ensure that the helmet is stored in a dry environment, away from moisture, and the packaging must be strong enough to protect the product from impact during transportation.

In addition to technical difficulties, helmet processing also faces strict requirements on durability, safety, environmental standards, as well as the problem of balancing quality, productivity and production costs. All these factors require manufacturers to continuously invest in technology, modern equipment, apply scientific production processes and train a team of skilled and dedicated workers.

Reviews

There are no reviews yet.