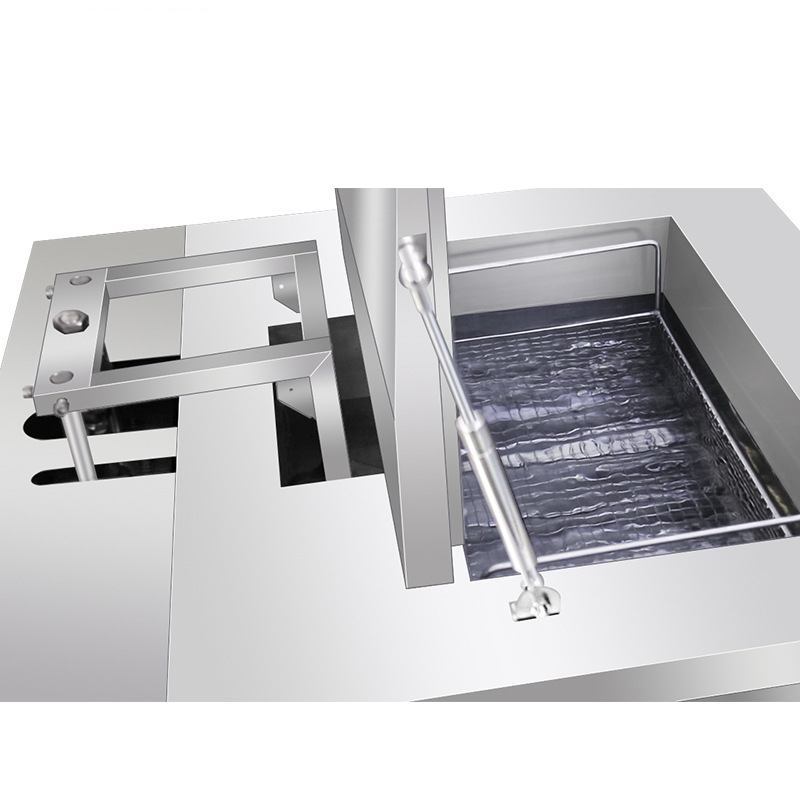

VietSkymen Ultrasonic Cleaner for CNC Products

- Brand: Vietskymen

- Frequency: 28-40KHz

- Technology : Ultrasound

- Application: cleaning objects and components in production

- Detailed specifications will be made to order to suit customer needs.

Stains often remain on CNC products after the machining process.

CNC-machined products often contain stubborn dirt, requiring a thorough cleaning process. Here are some common types of dirt:

- Metal shavings: This is the most common type of dirt, arising from the metal cutting process. The size of metal shavings is very diverse, from large, easily visible pieces to tiny dust particles. Metal shavings adhere very firmly to the surface of the product, especially small details, gaps, threads, etc.

- Machining oil: Cutting oil, lubricating oil is used in CNC machining process to reduce friction, cool cutting tool. Machining oil is often mixed with metal shavings, forming a viscous, sticky mixture that sticks persistently to the product surface.

- Environmental dust: During the processing, CNC products can also be contaminated with dust from the surrounding environment such as dirt, cement dust, fabric fibers, etc.

- Rust : If the CNC product is made from easily oxidized materials such as iron or steel, rust is also a problem that needs to be addressed. Rust not only affects the aesthetics but also reduces the quality and durability of the product.

- Other stains: Depending on the type of material and processing process, CNC products can also be contaminated with other stains such as glue, paint, ink, etc. Clearly identifying the type of dirt on CNC products will help you choose the appropriate cleaning method, ensuring optimal cleaning efficiency.

Time-consuming and labor-intensive, but are traditional cleaning methods really effective?

Traditional CNC cleaning methods, such as manual scrubbing, pressure spraying, and chemical cleaning, have been used for a long time, but they still have many limitations. First, these methods require a lot of effort and time. Manual scrubbing requires a lot of manpower and time, especially for complex and small parts. Not only that, the cleaning efficiency depends a lot on the skill and meticulousness of the operator. Pressure spraying requires specialized machinery and labor safety, and this process can also cause surface wear if not well controlled. Chemical cleaning requires soaking time and may require multiple steps to completely remove dirt. The management and disposal of chemical solutions are also complicated and expensive.

In terms of cleaning efficiency, traditional methods can lead to inconsistent quality, especially in hard-to-reach areas. The use of chemicals in cleaning can leave chemical residue or cause environmental pollution if not handled properly. Furthermore, mechanical methods such as scrubbing and pressure spraying can cause wear or damage to metal surfaces, affecting the accuracy and quality of the product.

Vietskymen ultrasonic tank eliminates business problems

In the context of modern production, ensuring the quality and cleanliness of CNC machine parts is an important factor that determines the performance and longevity of the product. However, traditional cleaning methods are often laborious, time-consuming and do not ensure consistent efficiency. To thoroughly solve these problems, VietSkymen ultrasonic tanks have become the first choice of many businesses.

VietSkymen ultrasonic tank uses advanced ultrasonic technology to effectively remove stubborn stains such as grease, metal dust, and impurities from the manufacturing process without damaging the metal surface. The ultrasonic cleaning process creates tiny air bubbles in the cleaning solution, helping to penetrate every corner of the machine part, ensuring high and uniform cleanliness. This is especially important for CNC machine parts with complex designs and high precision requirements.

Using VietSkymen ultrasonic tanks not only helps businesses save time and labor costs, but also minimizes the risk of damage to products. Instead of having to perform complicated and expensive manual cleaning steps, businesses only need to put the parts into the ultrasonic tank and let the machine clean automatically. This not only increases productivity but also ensures stable and consistent product quality.

Invest Now in VietSkymen Ultrasonic Tank – Effective Cleaning Solution for Businesses

Are you having difficulty cleaning CNC machine parts? Traditional methods take a lot of time and effort but still do not guarantee quality? Don’t worry, VietSkymen ultrasonic tank is the perfect solution for you!

Don’t let cleaning problems affect your productivity and product quality. Invest in a VietSkymen ultrasonic tank now to experience the difference!

Buy online via:

Website: https://skymen.vn/

Fanpage: https://www.facebook.com/vietskymen.vn

Or contact directly via Hotline: 0901.85.6888 for detailed consultation and quotation support.

Product Experience at the Manufacturing Facility

North: No. 30, Truong An Industrial Park, An Khanh Commune, Hoai Duc District, Hanoi City (Behind Thien Duong Bao Son).

South: 52 Street No. 36, Van Phuc Urban Area, Hiep Binh Phuoc Ward, Thu Duc City, Ho Chi Minh City.

Invest in VietSkymen ultrasonic tanks to improve product quality and production efficiency today! Contact us for detailed advice and to own the best ultrasonic cleaning machines!

Reviews

There are no reviews yet.