Dr.Ozone DK20 Industrial Deodorizer Ozone Machine, Max Processing Up to 6,000 m3/h

40,500,000₫

- Model: Dr.Ozone DK20

- Technology: Ozone Canada

- Material: Blue powder-coated steel shell

- Max processing capacity: 4,000 – 6,000 m3/h

- Power: 600W

- Dimensions: 75x55x40cm

- Wind pressure: 1.3kpa

- Applications: Industrial deodorization, industrial sterilization, industrial waste gas treatment.

- Production Place: HSVN GLOBAL CO.,LTD

What are the outstanding features and characteristics of Dr.Ozone DK20 industrial deodorizer Ozone machine?

Dr.Ozone® Model DK20 deodorizer Ozone generator is a line of industrial deodorizers, using a completely new improved design and modern devices that allow to treat and sterilize odor in larger areas quickly. Especially the machine can treat and sterilize smell effectively in the exhaust gas tube, kitchen duct. It also can integrate into large central control systems. The advantage of the Dr.Ozone DK20 line is to use an inox output of ϕ60 size, using the large capacity centrifugal fan with 1.3kpa pressure.

| Model | Processing capacity | Wattage | Size | Wind Pressure |

| Dr.Ozone DK20 | 4000 – 6000 m3/h | 600W | 75x55x40cm | 1.3kpa |

| Dr.Ozone DK40 | 6000 – 10.000 m3/h | 800W | 75x55x40cm | 1.3kpa |

| Dr.Ozone DK60 | 10.000 – 15.000 m3/h | 1000W | 75x55x40cm | 1.3kpa |

The great advantages of Dr.Ozone DK20 high-capacity deodorizer ozone machine:

- Exclusive rights design on the machine’s style and Ozone champer in on the market.

- High purification capacity, decomposes odors immediately.

- One ozone machine allows efficiently treat one or more odor smog chimney.

- Give ozone gas easily and flexibly enter the chimney, from one or more ozone intake points on the connected wind tube.

- Does not affect the ventilation system.

- No noise (<60 – 70dBA).

- Ozone is produced on-site by Dr.Ozone industrial ozone machine and is pumped into the exhaust gas tube. Then, it will remove most of the odor-causing substances, VOCs volatile organic substances.

Dr.Ozone DK20 deodorizer Ozone device can be used to replace the household ozone deodorizer lines, conventional ozone deodorizers in the deodorization request in high concentration or on a large area, many rooms, many areas. Model DK often effectively use in exhaust gas treatment, garbage house odor, CNC cutting workshop, laser workshop, industrial kitchen smoke smell, room disinfection, food storage room disinfection, killing mold on large areas.

The application of Dr.Ozone DK20 specialize in deodorizing and disinfecting industrial warehouses, medical rooms, drug and pharmaceutical warehouses

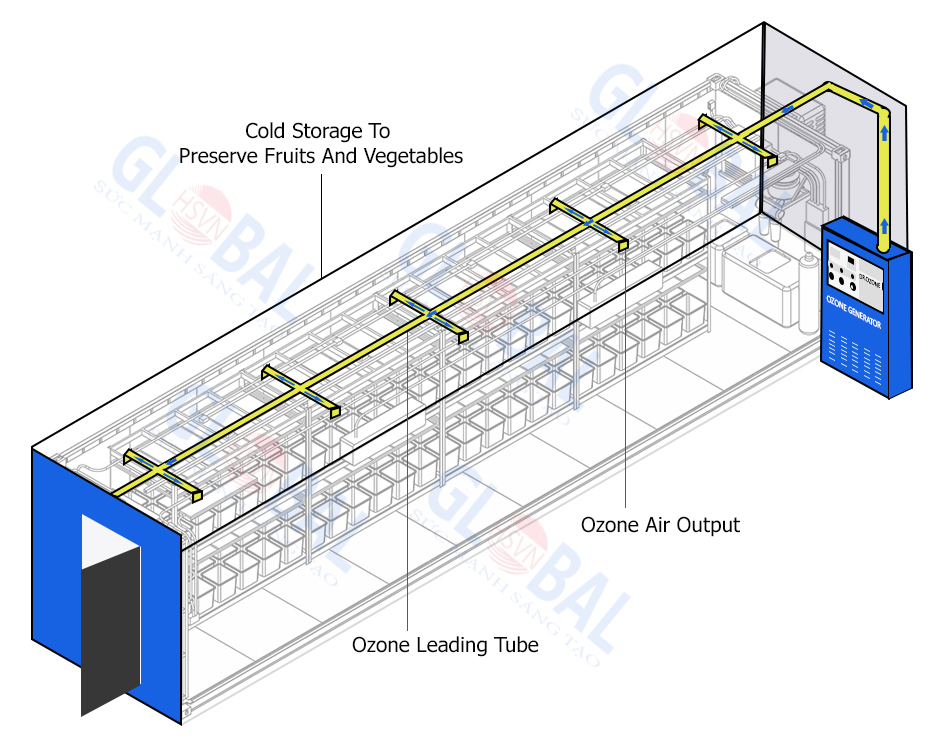

Application simulation of Dr.Ozone DK20 industrial deodorizer Ozone machine specializes in deodorizing and disinfecting industrial warehouses

Ozone technology is applied in exhaust gas duct deodorization. In the past, we often used the solution of industrial ozone machine with output ϕ9, prickling the duct directly. Although this method is still effective but not a high result, the ozone amount can’t be mixed quickly, so required gas leading tube request of 10-15 meters long. With the improvement of output size up to ϕ60, it makes the odor removal effect evidently fast, the odor molecule is easily broken down by the ozone molecule that fluctuates strongly in the gas stream, resulting in fast efficiency & windpipe length short to 50%.

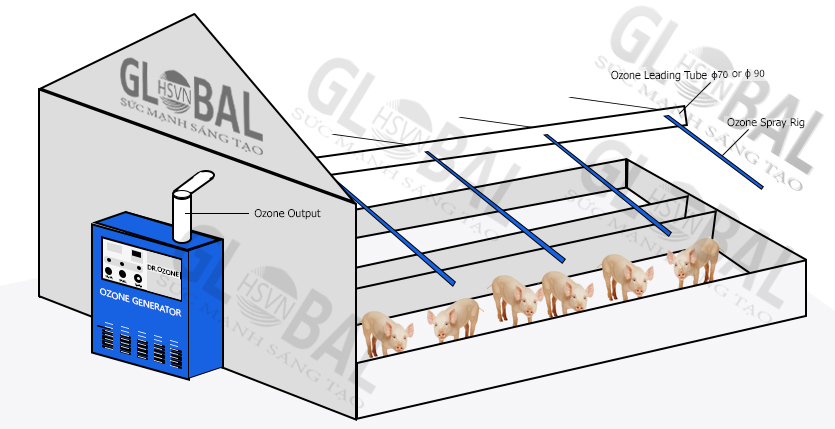

The model of using the Dr.Ozone DK20 industrial Ozone machine to deodorize & disinfect the barn

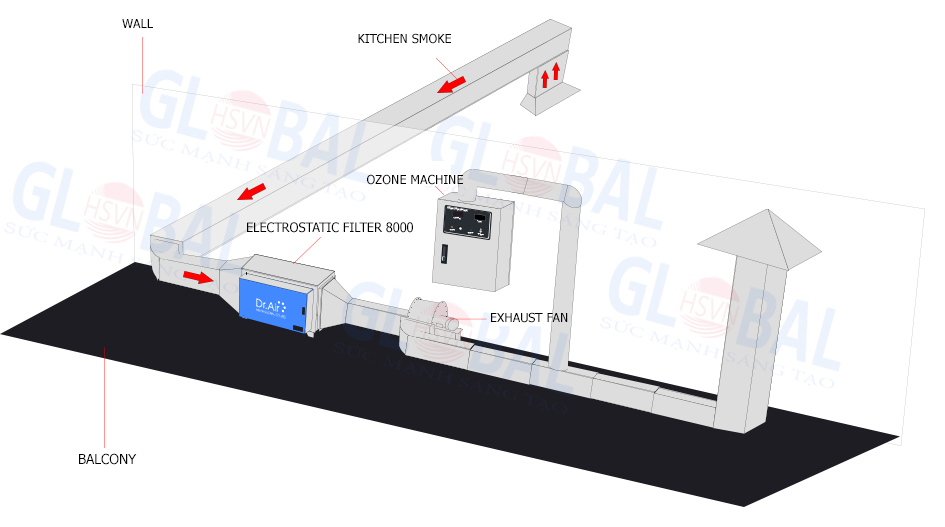

The application of Dr.Ozone DK20 industrial Ozone machine in treating exhaust gas & industrial kitchen smoke smell

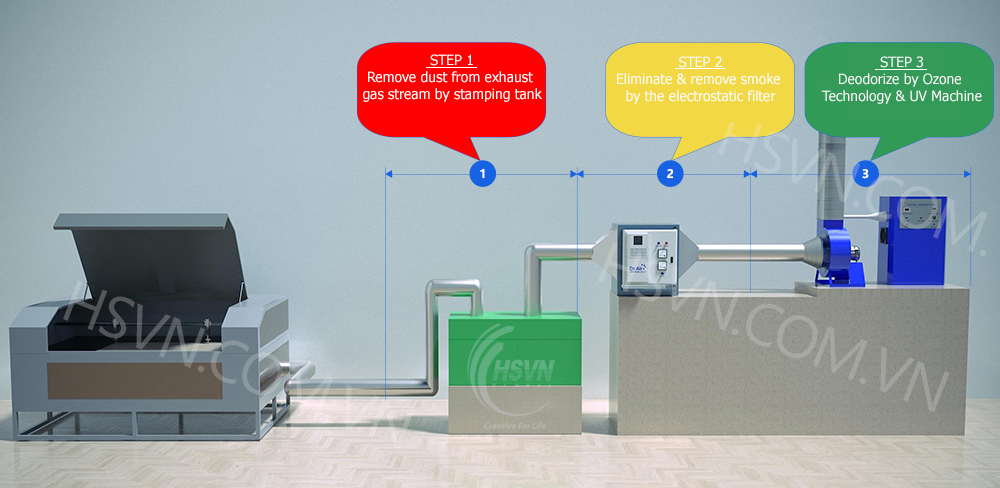

The treatment system simulation of Dr.Ozone DK20 deodorizer ozone machine

DK large-capacity ozone generator is used in the final stage of deodorizing industrial kitchen smoke. The system includes the industrial electrostatic filter Dr.Air KT – Another product of HSVN Global; The electrostatic filter has the effect of eliminating smoke, retaining the oil present in the kitchen exhaust gas, allowing only odors to pass through the system. Odor is sucked out by the wind duct system & centrifugal exhaust fan & 100% eliminated by a Dr.Ozone DK large-capacity ozone machine. This is the most “ADVANCED & COMPREHENSIVE” kitchen exhaust gas treatment system, bringing highly efficient and optimized for operating costs.

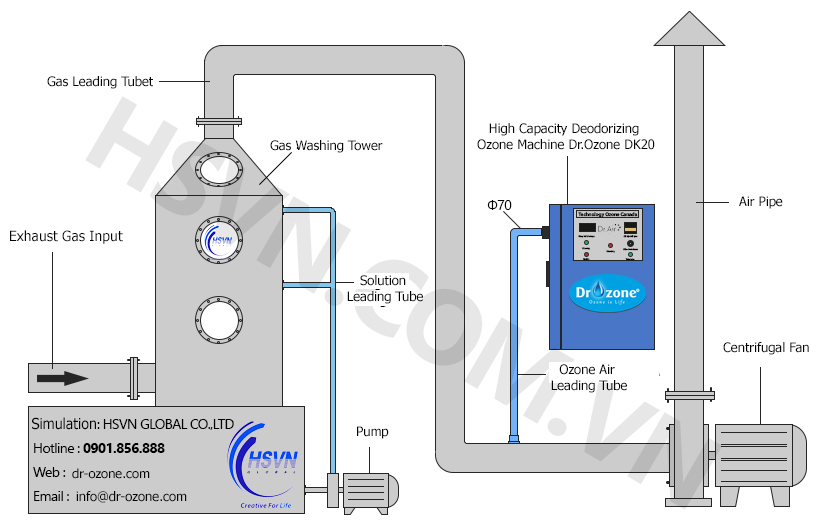

The application of Dr.Ozone DK20 industrial deodorizer Ozone generator in industrial exhaust deodorization

Model for deodorizing industrial exhaust gas by Ozone technology

Using Dr.Ozone DK20 professional ozone generator is one of the optimal methods for the model treating the exhaust gases of the industry, plastic sector, factory, solvent processing workshop, printing workshop, Laser cutting workshop, CNC or other exhaust smoke odor treatment needs that bring high efficiency as well as reduces operating costs.

The above industrial odor treatment model applies for treating industrial exhaust gas that contains a lot of dust and odors. The treatment process includes two steps:

Step 1. The dust part is completely treated through the Dr.Clean technology dust suppression tower system – Made by HSVN Global

Step 2. The odor part is completely treated by an industrial ozone machine.

Reviews

There are no reviews yet.