HS15000 Industrial Waste Gas Treatment Machine

- Treatment capacity: 15000m³/h

- Voltage: 380V/50Hz

- Capacity: 12.5kW

- Dimensions: 2650x2650x5800 mm

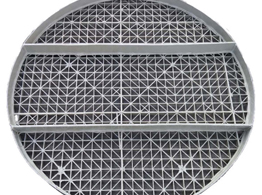

- Number of tubes: 121

- Pipe diameter: 168mm

- Tube thickness: 1 mm

- Pipe height: 2000 mm

- Case material: 1.5 mm thick stainless steel

- Flange diameter: 600 mm

HS15000 industrial exhaust gas treatment machine is a high-capacity exhaust gas treatment system, ensuring the amount of exhaust gas after treatment is below 50mg/Nm3, with a treatment efficiency of 99%. HS15000 is often installed behind gas scrubber towers for high-temperature exhaust gas or directly treats exhaust gas at the outlet (collection head into the system).

Another advantage is that the HS air filtration system uses high pressure water and solution washing technology, without the need for mechanical cleaning methods, thereby increasing equipment life and reducing system operating costs.

The above exhaust gas treatment model is applied to the exhaust gas treatment system of plastic recycling factories, CNC cutting machine odors, rubber cutting, industrial laser engraving, furnace exhaust gas treatment, incinerator exhaust gas treatment, colloidal ash exhaust gas, etc. In this model, we use a 3-step treatment method including:

- Dr.Clean brand industrial gas cleaning tower system includes air filter layers & air nozzles to clean and lower exhaust gas temperature.

- HS industrial smoke, dust, ash, etc. treatment system: is a device that collects particles using electrostatic force to remove particulate matter (PM) from exhaust gas. The advantage of HS industrial exhaust air purifier is that it processes large volumes of gas, a lot of dust, and is highly efficient even for small and ultra-small particles. The HS machine can process exhaust gas containing corrosive substances such as acids, wet materials, or high-temperature exhaust gas less than 100 degrees Celsius.

- Odor treatment stage uses Subgenerator odor burning technology from Germany or Dr.Air UV odor deodorizer from HSVN Toan Cau using UV technology (can use Ozone odor deodorizer instead). The basic principle of the odor deodorizer is to use high temperature to burn odor, or use the ability to break down odor molecules, VOCs with short-wave UV light or odor deodorization technology with Ozone gas from Dr.Ozone ozone blower.

Reviews

There are no reviews yet.