Dr.Air EU-5000 wet electrostatic filter for exhaust gas treatment, capacity 3200W

- Model: EU-5000

- Gas treatment flow: 5,000 m³/hour

- Overall dimensions (LxWxH): 2824 x 1870 x 2085 mm

- Hood size (WxH): 1120 x 1233 mm

- Input power: AC 380V, frequency 50Hz

- Power consumption: 3.2 kW

- Working voltage: 20 kV

- Number of filter levels: 1 filter level

- Number of inspection chambers: 2 chambers

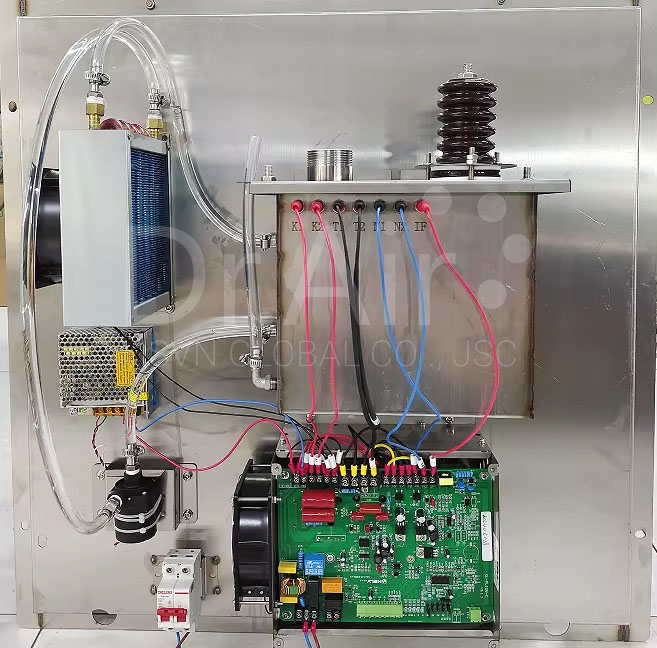

- Number of high voltage power supplies: 1 set

- Shell material: 201 stainless steel, 1.5mm thick (can be made of 304 stainless steel upon request)

After many years of development and practical application, the Dr.Air EU wet electrostatic precipitator series of HSVN Toan Cau has become a reliable choice for hundreds of factories and manufacturing plants nationwide. In order to optimize treatment efficiency, equipment durability and save operating costs, the new Dr.Air EU version has been officially launched with many outstanding improvements in structure, performance and smart operation .

OUTSTANDING FEATURES OF THE NEW VERSION

-

More solid structure: The body is machined with increased thickness from 0.95mm to 1.45mm , helping to increase the device’s lifespan and resistance to impact and harsh environments.

-

Comprehensive automatic washing system: If the old version only has a washing system on the top, the new version is designed to wash both the top and bottom . The number of nozzles is increased , making the cleaning process more efficient, saving maintenance effort.

-

Higher capacity cleaning pump: Increases water flow and pressure, ensuring thorough cleaning of the plates and filter walls in a short time.

-

Stainless steel piping system: Replace PVC piping system with anti-corrosion stainless steel piping , improving durability and aesthetics of the equipment.

-

Large, durable, stronger radial ceramic: Improves ion generation ability, stabilizes electric field, helps improve fine dust and exhaust gas filtration efficiency.

-

Upgraded voltage source: Enhanced ability to create strong electric field, more effective in handling polluted gas components, oil smoke, industrial dust.

-

Synchronous integration of the entire system: Previously, parts such as the hood, automatic cleaning kit, and main body were quoted separately. Now all are integrated into a unified block , easy to install, and synchronized when used.

-

Optimized filtration hierarchy: The old filtration system has too many layers, causing complexity and inefficiency. The new line reduces the number of filter layers, clearly separating the areas for treating oil smoke, dust, and ash , helping to optimize the efficiency of each stage.

Dr.Air EU has a wide range of applications, meeting the exhaust gas treatment needs of many different industries, including:

- Energy: Industrial furnaces, boilers, generator exhaust.

- Food processing: Treatment of smoke, odors and pollutants generated during processing.

- Waste management: Treatment of emissions from waste incineration.

- Production: Plastic granule production, textile shaping, electroplating, metal surface oxidation treatment

TECHNICAL SPECIFICATIONS TABLE

| Model | Flow rate (m3/h) |

Machine size (L*W*H) mm |

KTChùm (W*H)mm |

Input voltage | Power (KW) |

Working voltage (KV) | Filter level | Inspection chamber | High voltage power supply | |

| EU-5000 | 5000 | 2824*1870*2085 | 1120*1233 | AC380V/50HZ | 3.2 | 20 | 1 | 2 | 1 | |

| EU-10000 | 10000 | 4248*2085*2085 | 1335*1233 | AC380V/50HZ | 4.5 | 20 | 2 | 3 | 2 | |

| EU-15000 | 15000 | 4248*2300*2085 | 1550*1233 | AC380V/50HZ | 5.0 | 20 | 2 | 3 | 2 | |

| EU-20000 | 20000 | 4248*2300*2335 | 1550*1483 | AC380V/50HZ | 5.5 | 20 | 2 | 3 | 2 | |

| EU-25000 | 25000 | 4248*2300*2335 | 1550*1483 | AC380V/50HZ | 7.0 | 20 | 2 | 3 | 4 | |

| EU-30000 | 30000 | 5672*2515*2335 | 1765*1483 | AC380V/50HZ | 8.0 | 20 | 3 | 4 | 6 | |

| EU-40000 | 40000 | 5672*2730*2535 | 1980*1683 | AC380V/50HZ | 10.0 | 20 | 3 | 4 | 6 | |

| EU-50000 | 50,000 | 7096*2730*2535 | 1980*1683 | AC380V/50HZ | 11.0 | 20 | 4 | 5 | 8 | |

| EU-60000 | 60000 | 7096*2945*2535 | 2195*1683 | AC380V/50HZ | 12.0 | 20 | 4 | 5 | 8 | |

Project of treating exhaust gas from the process of drying soil to extract rare metals with Dr.Air EU horizontal wet electrostatic filter system

Boiler exhaust gas treatment project with Dr.Air EU-5000 horizontal wet electrostatic filter system

Outstanding advantages of Dr.Air EU:

|

|

Power supply

|

Electric field region:

|

|

|

Insulators

|

Maintenance door

|

|

|

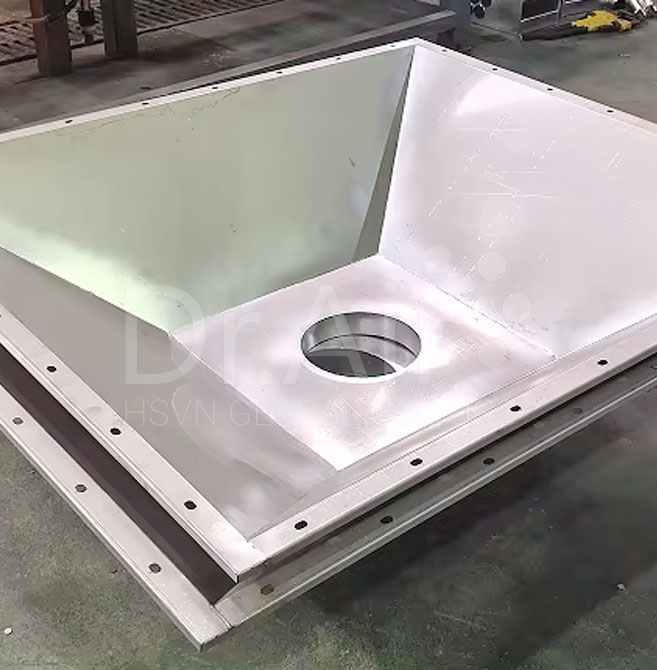

Drain

|

Speed reducerReducer coupling is used to connect the pipe and the filter. We can design the reducer coupling according to the diameter of the pipe.

|

Easy to clean

Cleaning the filter of the Dr.Air EU wet electrostatic precipitator is simple and quick, without disassembling the filter. Thanks to the smart design with tube-shaped electrode plates, the operator only needs to open the cleaning door and use a high-pressure water jet to clean the dirt on the filter surface.

Filter cleaning process:

- Disconnect power: Make sure the appliance is completely disconnected from the power source before cleaning.

- Open the cleaning door: Open the cleaning door of the purifier to access the filter.

- Spray cleaning: Use a high-pressure water jet to spray the entire filter surface, removing dirt and adhesives.

- Check and dry: Check the filter after cleaning, make sure there is no dirt left. Close the cleaning door and let the filter dry naturally or use a fan to dry faster.

With the above outstanding advantages, Dr.Air EU wet electrostatic filter is the ideal choice for factories and manufacturing enterprises that want to effectively treat exhaust gas, ensure a clean working environment and comply with environmental protection regulations.

Working principle

The operating principle of the Dr.Air EU wet electrostatic filter is divided into the following steps:

-

High voltage electric field generation: A high voltage of tens of thousands of DC volts is applied between the anode and cathode of the filter, generating a powerful electrostatic field.

-

Corona discharge: The strong electrostatic field causes corona discharge around the electrode wire, ionizing the air and generating a large number of negative ions and a small number of cations.

-

Charging of dust particles: The exhaust gas containing dust, mist and pollutant particles enters the device, these particles collide with negative and positive ions, gain electrons and become charged particles.

-

Dust collection: Under the influence of Coulomb force, charged particles move towards the opposite electrode. Positively charged particles are attracted towards the negative electrode and negatively charged particles are attracted towards the positive electrode.

-

Retention and removal of dust particles: When charged particles approach the electrode, they release their charge and are retained on the electrode surface. These dust particles are then washed away with water or a specialized solution, ensuring filtration efficiency and device longevity.

This process is continuous and cyclical, helping the Dr.Air EU wet electrostatic filter effectively remove pollutant particles from the exhaust air stream, providing cleaner and fresher air.

Equipment consulting and installation process

Dr.Air understands that each factory and enterprise has its own characteristics regarding exhaust gas. Therefore, we provide professional consulting and installation process for exhaust gas treatment system, ensuring optimal treatment efficiency for high temperature exhaust gas containing oil mist and steam:

1. Survey and analysis:

- Dr.Air’s team of experienced engineers will come to your site to conduct a site survey and make a detailed assessment of:

- Exhaust gas characteristics: Composition, temperature, flow, concentration of oil mist and water vapor.

- Installation space: Area, machine location, air duct.

- Treatment requirements: Output emission standards, pollution reduction targets.

2. Consulting and solution design:

- Based on the survey results, Dr.Air will advise customers to choose the most suitable Dr.Air EU model, ensuring optimal treatment efficiency and cost savings.

- The team of engineers will design a detailed exhaust gas treatment system, including:

- Layout diagram of equipment, gas pipes, electrical system.

- Select manufacturing materials appropriate to the emission characteristics.

- Calculate technical parameters such as capacity, filtration efficiency, pressure.

3. Installation and trial operation:

- Dr.Air will install the equipment according to the design drawings, ensuring safety and quality.

- After installation, the system will be tested to check the filtration efficiency, calibrate the parameters and ensure that it meets the technical requirements.

4. Operation and maintenance instructions:

- Dr.Air will provide detailed instructions to operators on how to use, inspect and maintain the equipment to ensure stable performance and long life.

- Provide detailed operation and maintenance manuals and 24/7 technical support.

5. Warranty and periodic maintenance:

- Dr.Air provides long-term warranty and periodic maintenance services according to customer requirements, ensuring that the exhaust gas treatment system always operates effectively and meets environmental standards.

With a professional and dedicated process, Dr.Air is committed to providing optimal exhaust gas treatment solutions, helping customers feel secure about air quality, saving operating costs and contributing to environmental protection.

PHOTOS OF ACTUAL PROJECTS THAT DR.AIR HAS IMPLEMENTED

Reviews

There are no reviews yet.