Dr.Air DS-13L drilling rig diesel engine exhaust gas treatment machine

- Model: DS-13L

- Exhaust flow: 13L

- Engine capacity: 200-240 KVA

- DOC (Oxidation Catalyst) filter size: φ305*100

- DPF (particulate trap) filter size: φ305*254

- Treatment efficiency: 95%

- Allowable back pressure: 8.5 Kpa

- Treatment technology: DPF, DOC

- HC purification rate: 60-90%

- NOx, NO, NO2 purification rate: 20%

- PM purification rate: 95%

- CO purification rate: 609-90%

- SO2, SO3 purification rate: 30%

- Noise level: 10dB

- External material: 201 stainless steel

- DPF technology dust-catching material: Honeycomb ceramic

- DOC Technology Catalyst: Oxidizer

- Catalyst activation temperature: 270 degrees C

- Initial return pressure <=9 Kpa

In the context of increasing concern about environmental pollution, finding effective exhaust gas treatment solutions becomes urgent. Dr.Air DS-13L Diesel engine exhaust gas treatment machine was born to meet that need, providing a green, sustainable solution for businesses in the heavy industry.

Specifications

- Model: DS-13L

- Exhaust flow: 13L

- Engine capacity: 200-240 KVA

- DOC (Oxidation Catalyst) filter size : φ305*100

- DPF (particulate trap) filter size : φ305*254

- Treatment efficiency: 95%

- Allowable back pressure : 8.5 Kpa

- Treatment technology: DPF, DOC

- HC purification rate: 60-90%

- NOx, NO, NO2 purification rate: 20%

- PM purification rate : 95%

- CO purification rate : 609-90%

- SO2, SO3 purification rate : 30%

- Noise level : 10dB

- External material: 201 stainless steel

- DPF technology dust catching material : Honeycomb ceramic

- DOC technology catalyst : Oxidizer

- Catalyst activation temperature : 270 degrees C

- Initial return pressure <=9 Kpa

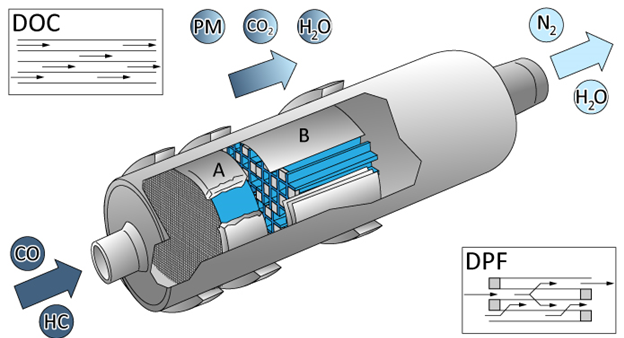

Detailed structure

Dr.Air DS-13L diesel exhaust treatment machine is a complex system, designed to remove pollutants in diesel exhaust before releasing them into the environment. Below is the detailed structure of the machine:

1. Body

- Housing: Usually made of stainless steel or composite materials, ensuring durability and corrosion resistance in marine environments.

- Support frame: Provides stability to the entire system.

2. Fan system

- Industrial fans: Create negative pressure to draw exhaust gas from the engine into the treatment system.

- Motor: Provides power for the fan to operate.

3. Filter chamber

- Primary filter: Removes large dust particles and debris.

- DPF (Diesel Particulate Filter): Traps ultra-fine dust particles and soot.

- DOC (Diesel Oxidation Catalyst) Filter: Converts toxic gases such as CO, HC into CO2 and H2O.

4. Control system

- Controller: Controls fan speed, system operating temperature, and other parameters.

- Sensors: Measure parameters such as pressure, temperature, exhaust gas flow to adjust the treatment process.

- Display screen: Displays the machine’s operating parameters, helping users easily monitor and maintain.

5. Piping system

- Intake pipe: Conducts exhaust gases from the engine into the system.

- Exhaust pipe: Releases clean air into the environment.

6. Other parts

- Drain valve: Helps drain dirt accumulated in the DPF filter.

- Pressure Sensor: Measures back pressure across the DPF filter to determine when regeneration is needed.

- Cooling system: Helps cool engine components, especially the DPF filter during regeneration.

How does Dr.Air DS-13L drilling rig diesel engine exhaust gas treatment machine treat exhaust gas?

DS-13L diesel engine exhaust treatment machine is composed of 2 filter parts: DOC (oxidation catalyst) and DPF (dust filter). The combination of these 2 technologies brings comprehensive efficiency in treating dust and toxic gas compounds.

The operating process of the equipment is as follows: When the DS-13L diesel exhaust treatment machine is running, the exhaust gas of the diesel engine passes through the honeycomb catalyst and the particulate filter. At that time, the polluting gases (HC, CO, PM, NOx) are rapidly oxidized under the effect of the catalyst coating on the surface of the carrier (urea solution), to transform into CO 2 , H 2 O and other substances that are more environmentally friendly.

Operating principle of diesel engine exhaust gas treatment equipment

Advantages of Dr.Air DS-13L drilling rig diesel engine exhaust gas treatment machine

Dr.Air DS-13L exhaust gas treatment machine is specially designed for drilling rigs with outstanding advantages:

- High filtration efficiency : Effectively removes ultra-fine dust, NOx, SOx and VOCs, meeting international emission standards such as Euro 5, Euro 6, protecting the environment and public health.

- Durable and stable : Made from anti-corrosion materials, the machine operates stably and durably in harsh marine environments.

- Cost savings : Reduces fuel consumption and extends engine life, thereby reducing maintenance and repair costs.

- Easy operation and maintenance : Automatic control system makes operation simple and easy to monitor. Maintenance-optimized design reduces operating costs.

- Regulatory Compliance : Meet environmental standards, helping businesses comply with regulations and avoid legal risks.

- Increase competitiveness : Using modern technology shows concern for the environment, attracting customers with environmentally friendly products and services.

- Diverse applications : Suitable for many types of diesel engines and can be installed on many types of machinery and equipment in the mining, construction, energy and marine industries.

Things to note when using diesel exhaust treatment equipment

When using diesel engine exhaust treatment equipment, the following points should be noted to ensure efficiency and safety:

- Follow the operating instructions : Read and operate the equipment according to the manufacturer’s instructions, and perform regular maintenance as recommended.

- Use fuel and fluids correctly : Use only standard diesel fuel and genuine urea (AdBlue) fluid for the SCR system, undiluted.

- Periodic Inspection : Regularly check components such as filters, sensors, and solenoid valves; replace damaged or expired parts.

- Cleaning and maintenance : Clean filters periodically to prevent clogging and replace urea solution when levels are low.

- Safety Precautions : Avoid contact of urea solution with eyes, skin or digestive tract, and keep away from heat or sparks when working with the system.

- Compliance with legal regulations : Ensure equipment operates according to emission standards and conduct periodic inspections as required.

These precautions help ensure the equipment operates efficiently, safely and complies with environmental regulations.

Reviews

There are no reviews yet.