Dr.Ozone D10S Industrial Ozone Generator 10,000mg/h High Capacity Ozone Machine

15,500,000₫

- Model: Dr.Ozone D10S

- Ozone quantity: 10 g/h

- The largest Ozone concentration (condition supply oxygen 3l/min, oxygen concentration > 80%): 55 g/m3

- Air flow: 80 l/p

- Air filter: Included

- Oxygen concentrator unit: Not include

- H2O-Green Cooling: Not include

- Power Consumption (0 – max): 170W

- Circuit size: 96x44x44mm

- Ozone Output (Φ): 6mm

- Maximum pressure: 0.1pa

- Voltage: 220V/50hz

- Working environment temperature: <35 °C

- Ideal temperature: <30°C

- Working environment humidity: <80%

- Ideal humidity: <70%

- Machine dimensions: 550 (W) x 250 (D) x 550 (H) mm

- Weight: 14kg

- Warranty: 18 months for ozone generator and 12 months for its accessories

What are the outstanding features and characteristics of Dr.Ozone D10S?

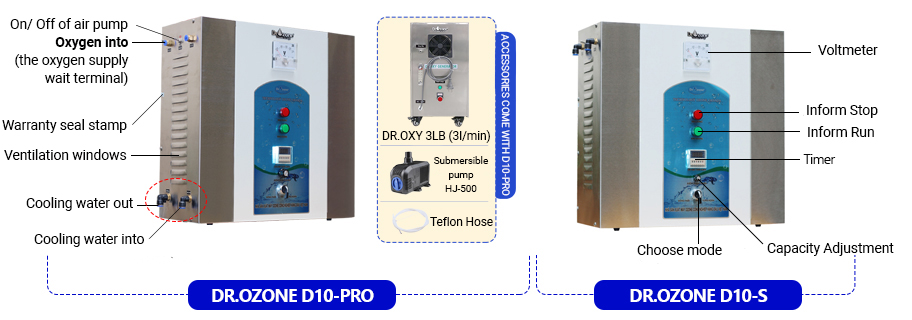

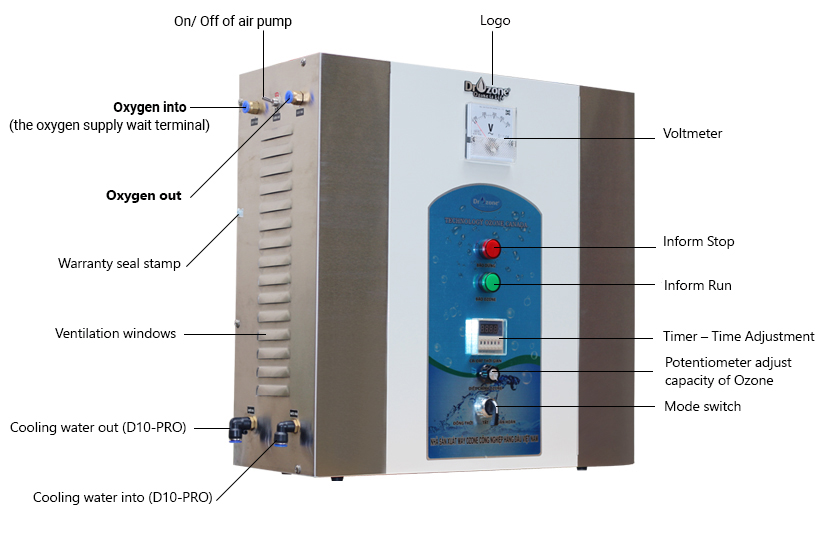

The industrial ozone generator Dr.Ozone D10 – a product “MADE BY HSVN GLOBAL” is designed in a traditional style with many completely new improvements of the V2020 version to help the machine can operate & serve versatile in many civil and industrial sectors that requires the use of Ozone technology. One of the important improvements of this machine line is that we upgraded to 2 versions of D10 capacity 10g/h for customer choice, including D10S & D10-PRO.

The outstanding advantage and differences of the two versions industrial ozone machine 10g/h

The Ozone generator DR.OZONE® D10S: Directly cooled by air & heatsink aluminum fan. The machine uses Auto-Cooling technology to ensure the safety of the machine by automatically shutting down when the system temperature is too high.

The industrial ozone machine DR.OZONE® D10-PRO: Integrated H20-Green cooling technology by water helps to cool down the temperature of the launch chamber, reducing ozone loss status during the active process and increasing the life of equipment and accessory. In addition, the D10-PRO machine is also integrated with Auto-Cooling technology to protect the system & heatsink aluminum fan, do physics. The easy detect external difference between the D10s and D10-PRO is that the D10-PRO side has 2 valves supply and draining cooling water.

The upgraded features are only available on Dr. Ozone’s industrial Ozone machine 10g/h that the cheap Ozone machine lines on the market are not included

- Integrated a pure oxygen supply wait device means that users can supply pure oxygen to the ozone machine by industrial oxygen generators, medical oxygen generators for the purpose of increasing Ozone concentration (PPM) and ozone capacity (GH).

- Time adjustment potentiometer 0g/h – MAX: 100% industrial ozone generators of Dr.Ozone all integrated Ozone capacity adjustment feature, which allows users to customize the Ozone capacity level according to their needs from 0h/g to Max (Ozone capacity as in specifications). This is one of the important features and a technological highlight that is different from 100% of cheap ozone machines on the market.

- Auto-cooling technology: The current most advanced Canadian technology producing Ozone circuit, allowing to control the operation of the machine (off the machine), ensuring the safety of equipment and components in case of machine temperature (control circuit board) increase too high. Auto-cooling is also one of the latest upgrades applied for the industrial Ozone machine version at the end of 2019.

- Inlet gas separator: The inlet gas filter unit is a new integration of product structure that helps to prevent dust from moving into the Ozone chamber & prevent moisture, filter impurities in the gas to increase Ozone concentration & capacity, better protect the ozone generator chamber.

- Cooling technology by H2O-Green water: This integration is exclusive to the D10-PRO ozone machine that cools the ozone-generating chamber (producing high heat ) continuously. Cooling water is passed through the launch chamber to take away the produced heat and bring it out. From that maintaining a stable temperature and reducing ozone attrition, increasing the conversion rate of Oxygen into pure Ozone.

Instructions for installing the machine to use when without or with oxygen machine support

For the D10-PRO, it is necessary to use one submersible pump (included with the machine) and a cooling water tank. Firstly, connect the submersible pump and the silicone leading hose to help supply the coolant water into the coolant water inlet. Connect the water leading to bring the coolant water from the machine back to the tank according to the circulation mechanism.

General instructions for the ozone machine D10S and D10-PRO

If you need to use the machine immediately, just use the silicon hose (included with the machine) to connect the Oxygen output & Oxygen input, turn on the gas pump switch. After that, connect the machine with the power supply and it can be used.

For the case of using a pure oxygen supply machine to support the ozone machine operation, as well as the need for the high concentration of purified Ozone gas to take disinfect process, connecting the oxygen machine to the system is very simple. Firstly, turn off the internal gas pump switch. After that, connect the output of the oxygen machine with the outlet to the oxygen inlet of the ozone machine, which is the oxygen supply wait terminal. The final is to connect the machine with the power source and use it.

Reviews

There are no reviews yet.