Dr.Air KT16000 Industrial Electrostatic Filter

160,000,000₫

- Model: Dr.Air KT16000

- Wind flow: 16000m3/h

- Machine size (LxWxH): 1265x685x1420mm

- Case: Carbon Steel (Q235A – 2mm).

- Filter dimensions (LxWxH): 510x360x480mm

- Filter membrane dimensions: 25x515x480mm

- Number of filters: 4

- Filter membrane plate thickness: 1mm – Aluminum alloy.

- The number of Tungsten threads: 64.

- Power: 200W

- High voltage: 12000V

- Low voltage: 7000V

- Pressure resistance level: 200PA

Dr.Air KT16000 industrial electrostatic filter uses 2 control boxes & 4 filters, 2 independent floors, allowing faster and more optimal processing capacity. Electrostatic filter application of the Dr.Air KT16000 is suitable for treating exhaust gases of large-scale industrial kitchens, restaurant kitchens and other dust & smoke treatment applications where an exhaust fan is installed about 16000m3/h.

Advantages of electrostatic filter have good smoke removal & oil filtration ability with efficiency up to 98%, easy integration into existing exhaust gas treatment system. In addition, electrostatic filtration combined with much other equipment such as Dr.Air AA filter box, Dr.Clean adsorption stamping tower, Dr.Ozone ozone deodorizer machine, … brings thorough treatment performance.

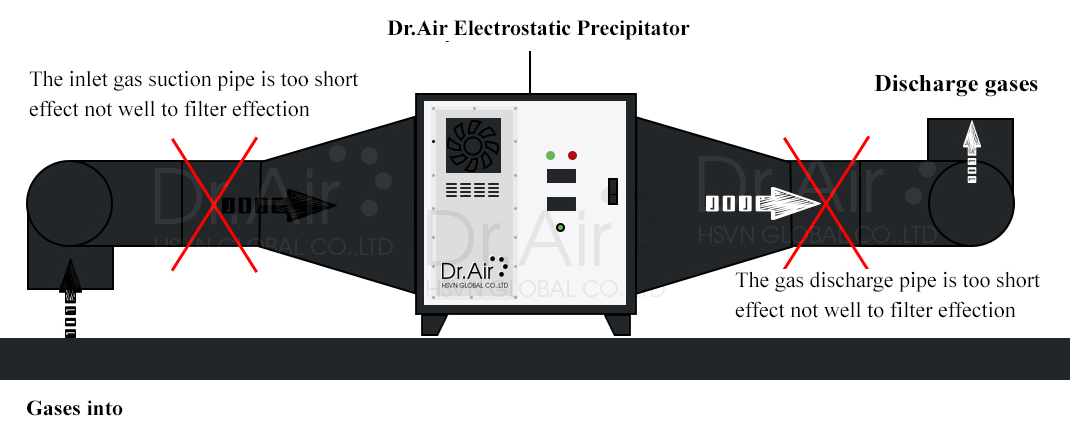

Some notes when installing the industrial electrostatic precipitator:

Avoid installing the length of the inlet and outlet exhaust air pipe too short

The length of the inlet exhaust gas leading pipe needs to be more than 3 times the pipe diameter, the exhaust gas outlet through the electrostatic filter needs to be larger than 2 times the pipe diameter.

The inlet and outlet exhaust gas pipes are connected to other equipment or exhaust fans by flexible connect hoses. In addition, for the best performance of the electrostatic precipitator, it is required that the exhaust fan be installed behind the electrostatic precipitator.

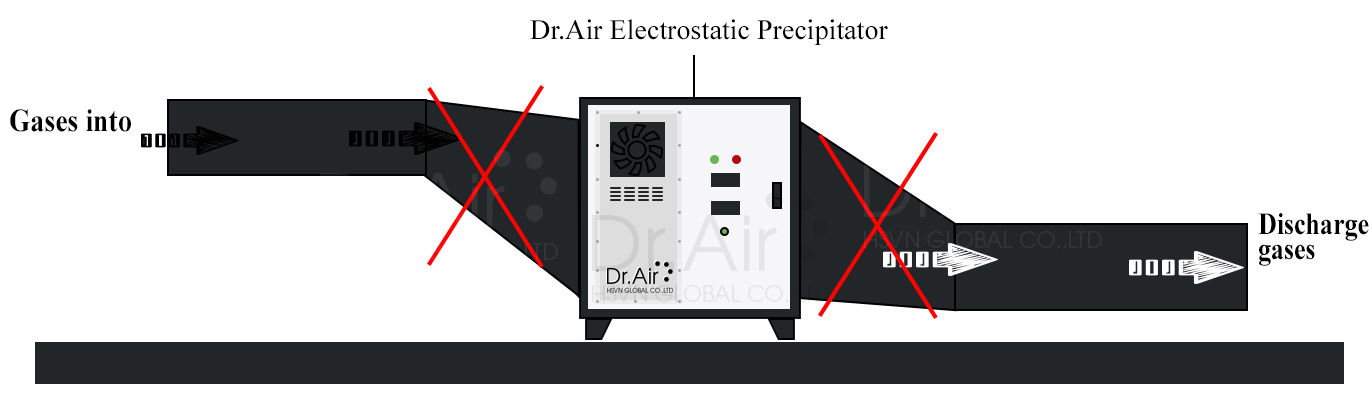

Avoid designing the gases capture suck in the wrong way

The angle of the gases capture suck needs to be tilted at an angle greater than or equal to 60o, balanced, located on a straight line with the center of the electrostatic filter to ensure the best air circulation, evenly distributed through the electrostatic filters, increasing the processing efficiency, offload for the position.

Reviews

There are no reviews yet.