Dr.Ozone D30S Industrial Ozone Machine 30,000mg/h High Capacity Ozone Generator

75,000,000₫

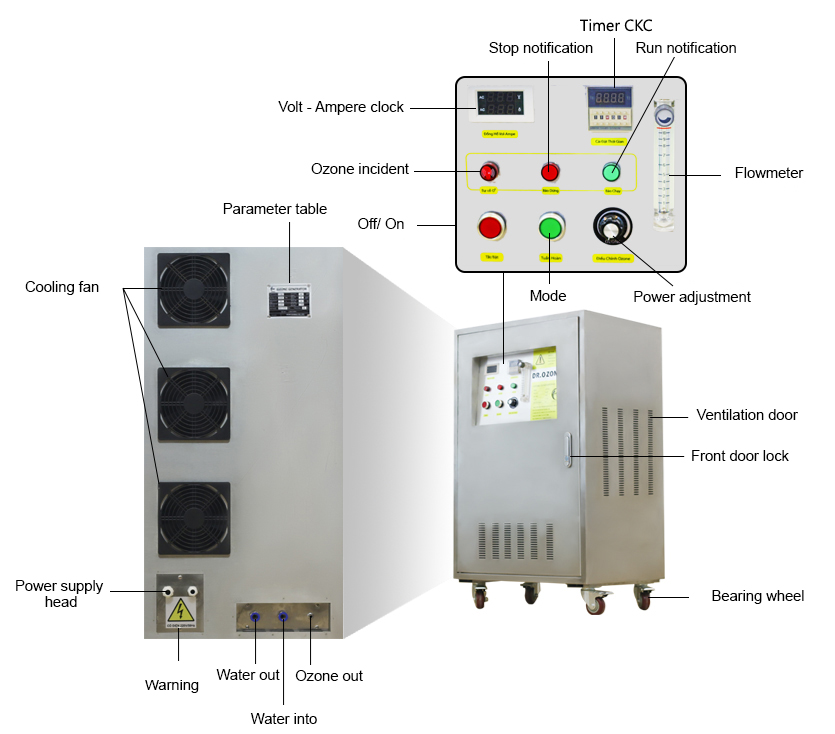

- Model: Dr.Ozone D30S

- Ozone capacity: 30 g/h

- Maximum Ozone concentration: 85 g/m3

- High voltage: 6 KV

- Designed chamber lifespan: > 10 years

- Machine operation mode: Continuous, cyclic

- Oxygen air flow: 5 – 6 L/ph

- Voltage 220V50Hz: 900W

- Electric current: 4A

- Ozone output: Ф10

- Maximum chamber pressure: <2 Bar

- Cooling way: Water cooling for the inner electrode and fan for the outer electrode.

- Cooling water temperature: <25oC

- Diameter of cooling conductor: 12mm

- Outlet cooling water pressure: <3 bar

- Ideal machine ambient temperature: <30oC

- Working environment temperature: <35oC

- Ideal machine ambient humidity: <70%

- Working environment humidity: <80%

- Machine dimension: 650 x 1100 x 500 (have wheels)

- Shell material: 304 inox

- Ozone air conductor: Teflon, Ф9

Dr.Ozone D30S industrial ozone machine product features:

Dr.Ozone D30S industrial ozone machine owns new design & version of V2019 improved in gas separation technology, ozone chamber, plasma technology, manufacturing techniques, shell design for better heat dissipation, stable power, and reduced loss to 0%. Dr.Ozone D30S has the same size as the D40S, D50S model.

- Apply improved technology of particle separation and gas separation with Zeolite materials; industrial packed oxygen filter columns follow the medical standard with the concentration of pure oxygen supplied to the ozone generator reaches over 92% at the temperature of 5 – 23oC, humidity is less than 70%; the lifespan of filter columns is 10,000 hours is equivalent to the filter column of other famous medical oxygen machine brands.

- Using effective insulating and anti-oxidation materials: Ozone generator chamber uses 444 blue powder coating stainless steel shell and 304 inox, insulated by uPVC plastic – (Polyvinyl chloride unplasticized) is a type of plastic that does not contain plasticizers, fire-resistant ability, recyclable and friendly with the environment; Ozone conductor “Teflon” is made from polymer compound contain fluorinated and carbon organic chemical has the ability of heat resistant, oxidation resistant, high wear resistance, non-adhesive, high electrical insulation, non-flammable and environmentally friendly.

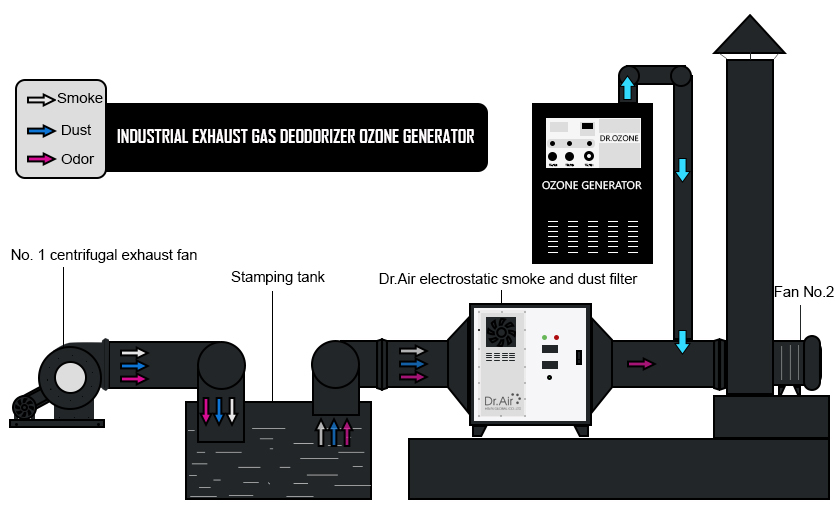

Application of D30S Ozone Generator In Emissions Treatment Of Printing Workshop, Laser Cutting Workshop & CNC Cutting Workshop

The exhaust gas of the printing workshop besides dust, ink particles also contains many other gases such as Methylene Chloride, Methylbenzene, Ethyl acetate, VOC volatile organic matter… Therefore, the exhaust gas treatment model is a system that includes:

- Dust stamping tank that reduces smoke & odor: Using ordinary water or industrial absorb solutions.

- Electrostatic filter system: Electrostatic precipitation filte technology is widely used in the treatment of industrial kitchen smoke, furnace exhaust gas, industrial dust. It has the effect of smoke removal, oil filter, dust confinement.

- Ozone D30S ozone machine: The main effect of deodorizing in the final stage, D30s has an ozone capacity of 30g/h, can handle an exhaust gas flow of 30000m3/h with ozone concentration in the air reaching 0.5ppm threshold.

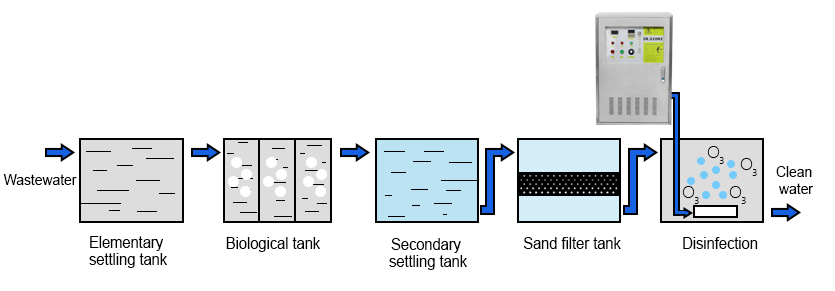

Application of Ozone Machine High Capacity In Industrial Wastewater Color & Water Odor Treatment Process

The industrial wastewater treatment process includes many stages in which Dr.Ozone D30S integrated into the system in two processes: Disinfection & Decolorization of water.

The ozone machine will inject into the 2nd tank (phase 2) right after the settling tank & before the water purification stage through the Carbon tank & sand tank system. The main effects of Ozone in the above model include:

- Reduce trihalomethanes in supplied water.

- Improve the color & odor quality of water by removing odor-causing gas compounds such as H2S, Ammonia,…

- Disinfects & removes odor-causing bacteria, bacterias in water and color bacteria.

- Removes organic matters such as iron and manganese.

The Dr.Ozone industrial ozone generator is widely applied in treating industrial exhaust, wastewater treatment, domestic water treatment, disinfecting in medical fields not only in Vietnam but all over the world. With strong oxidizing properties, self-sufficient ability, Ozone is completely an economical, high-efficiency alternative to normal disinfectants and water treatment chemicals.

Reviews

There are no reviews yet.