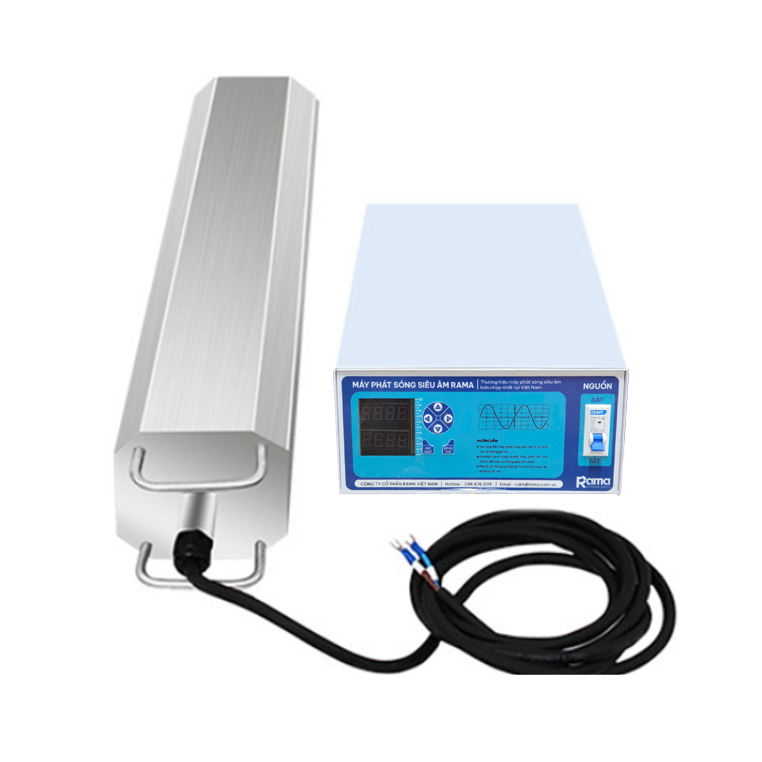

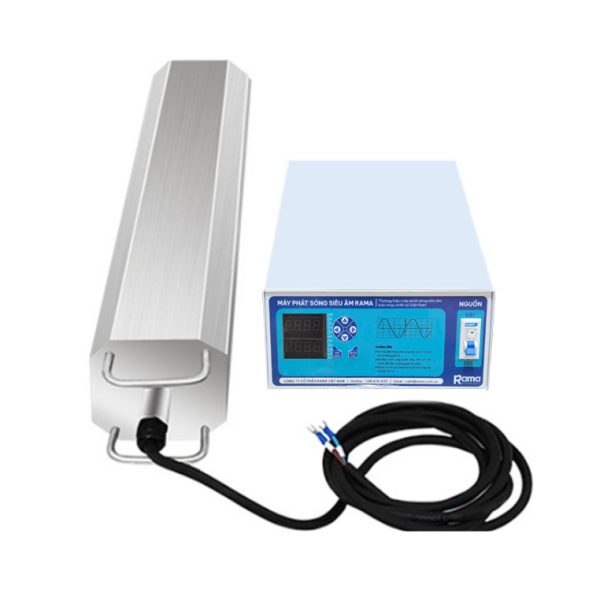

Wave generator – industrial ultrasonic vibrator Rama GH600 – GH3000

- Model: Rama GH

- Ultrasonic frequency: 28/40KHZ

- Capacity: 600W – 3000W

- Size: Customized

Ultrasonic generator is the source that generates and supplies ultrasonic energy to the ultrasonic transducer with suitable frequency (28khz – 40khz), by converting the main power source (220V or 380V, 50Hz or 60Hz) into high frequency alternating current (AC) pulse signal or sinusoidal signal.

Technical specifications of Rama GH industrial ultrasonic generator

| Model | GH600 | GH900 | GH1200 | GH1500 | GH1800 | GH2100 | GH2100A | GH2700 | GH3000 |

| Frequency | 40kHz | 40kHz | 40kHz | 40kHz | 40kHz | 40kHz | 40kHz | 40kHz | 40kHz |

| Capacity | 0-600W | 0-900W | 0-1200W | 0-1500W | 0-1800W | 0-2100W | 0-2100W | 0-2700W | 0-3000W |

| Diameter | 140mm | 140mm | 140mm | 140mm | 140mm | 140mm | 140mm | 140mm | 140mm |

| Length | 300mm | 450mm | 600mm | 750mm | 900mm | 1050mm | 1200mm | 1350mm | 1400mm |

| Material | SUS 304 | SUS 304 | SUS 304 | SUS 304 | SUS 304 | SUS 304 | SUS 304 | SUS 304 | SUS304 |

| Number of vibrating heads | 12 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 |

Ultrasonic cleaning technology is being developed and is increasingly used in many fields. Thanks to its outstanding advantages such as fast cleaning, no scratches on objects, no need to use many chemicals, ultrasonic waves have been applied in many different fields such as: cleaning eyeglasses, cleaning machine components, cleaning medical instruments, cleaning jewelry… Applied in industry, ultrasonic cleaning also plays an important role.

Ultrasonic generator structure

The structure of the 40kHz Rama ultrasonic generator includes the following parts:

- Machine case: made of stainless steel with quality machining details to ensure strength and sturdiness

- LED display panel: display function of current intensity (A), ultrasonic frequency (kHz), working time

- Ultrasonic wave generating circuit : has the function of converting the used voltage to high frequency voltage, mechanical oscillation of the same frequency. This is the most important part of the ultrasonic generator.

- Control buttons: including ON/OFF button, Time button, increase/decrease button, power control…

How an ultrasonic generator works

Whether used in industrial or domestic cleaning, ultrasonic generators work on the principle of generating ultrasonic waves . Depending on the wave generator, the waves generated have different frequencies. Low-frequency ultrasonic waves are suitable for cleaning large objects with few details; while high-frequency ultrasonic waves are used to clean small objects.

Ultrasonic waves create a series of compressions and expansions for the surrounding environment. When ultrasonic waves are propagated in water or solvents, they will impact the water molecules, causing these molecules to contract and expand continuously, leading to the creation of hundreds of thousands of small air bubbles. The air bubbles penetrate the surface of the object, the tiny air bubbles only exist for a short time and then quickly burst, creating a huge shock wave, washing away the dirt on the surface of the object.

Outstanding advantages of Rama GH industrial ultrasonic generator

With the above operating principle, the Rama GH industrial ultrasonic generator has the following advantages:

- Effective for cleaning many objects made of different materials.

- Easy operation control

- The machine can easily change capacity to suit each actual usage need.

- No need to use many chemicals for cleaning

- Able to wash large quantities of utensils at the same time, in a short time

- No need to use cleaning products

- Minimize the number of personnel operating the equipment

>>> READ MORE: Ultrasonic Transducer

Rama Vietnam is a reputable brand providing large and small sized ultrasonic generators and ultrasonic cleaners . In addition to available products, Rama accepts design and production according to PO orders. To learn more about Rama ultrasonic cleaning tanks, please contact the hotline for free consultation and quick quotation.

Reviews

There are no reviews yet.