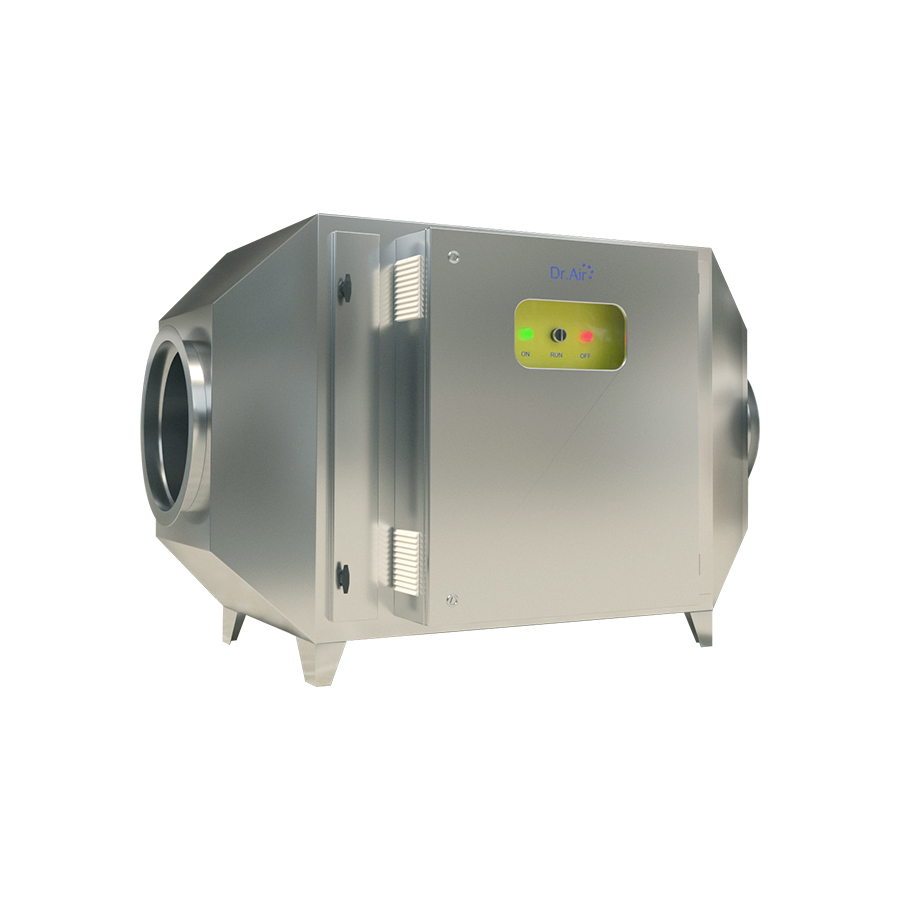

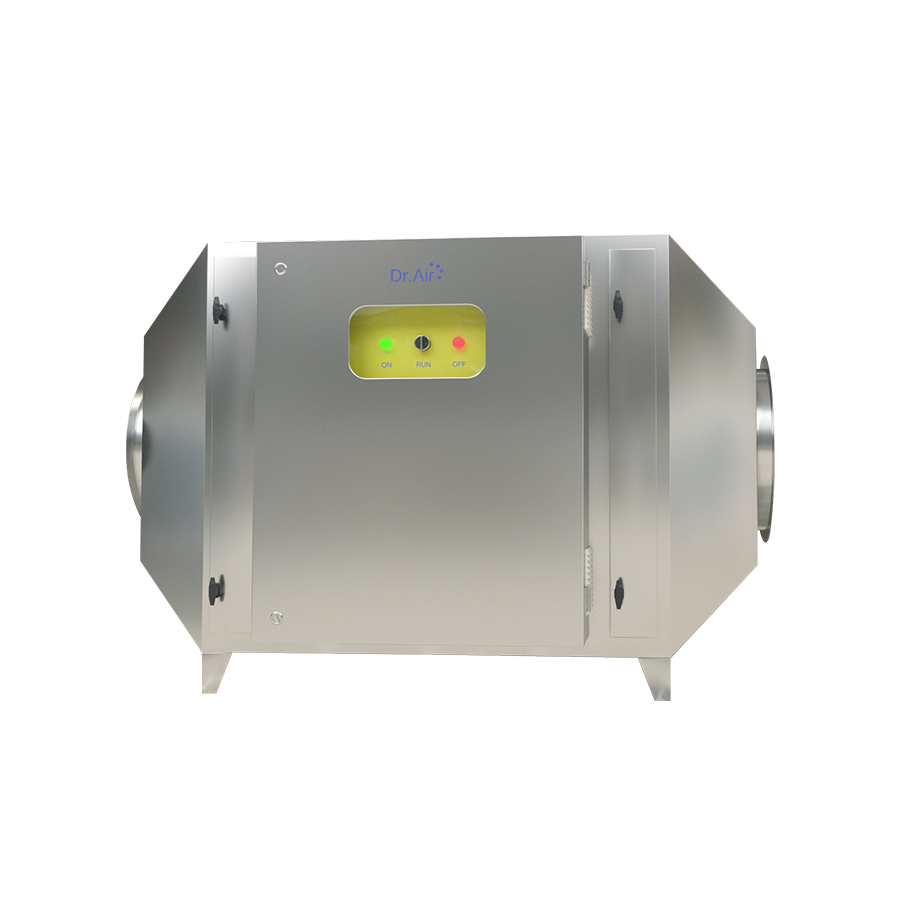

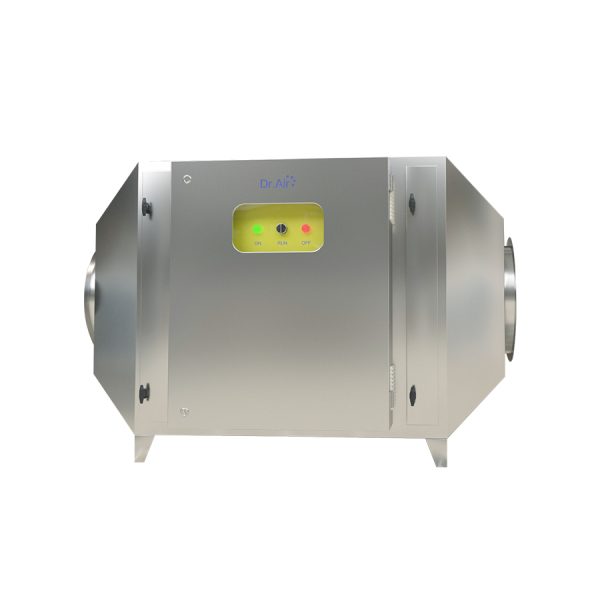

Dr.Air UV 5K Industrial Waste Gas Treatment UV Machine

- Model: Dr.Air UV-5K

- Flow rate: 5000 m³/h

- Voltage: 220 VAC

- Capacity: 2400W

- Number of UV bulbs: 16

- Pressure resistance: <150Pa

- Dimensions: 1350 x 1200 x 1160 mm

- Flange: Ø 300

- Material: stainless steel 201

Dr.Air UV industrial exhaust gas treatment UV machine integrates 2 technology platforms including UV and Ozone deodorization technology. Each technology has its own characteristics but the common goal is to deodorize industrial exhaust gas, industrial kitchen smoke, CNC cutting machines, etc.

The structure of the UV machine includes 2 main parts: primary filter and UV deodorizing system. In which, the primary filter only has the effect of filtering coarse dust. In case the exhaust gas has been treated to remove smoke, filter grease or has a dust filtering system in front, there is no need to use the primary filter.

Deodorization with UV Technology

Short-wavelength UV light energy breaks down most odorous compounds such as benzene, toluene, xylene, organic or inorganic compounds by shining UV rays on toxic gas streams. Under the influence of UV rays, these toxic substances are decomposed, broken down, and become friendly substances such as CO2 and H2O.

Dr.Air UV uses UV bulbs that produce Ozone

During the process of UV rays interacting with the air flow in nature, UV rays break down the molecular structure of oxygen, producing ozone (Oxygen bonds are broken into Oxygen O atoms, and at the same time combine with Oxygen to create Ozone O3). Because Ozone has strong oxidizing properties, it easily breaks down volatile organic compounds VOCs.

UV + O2 -> O- + O

O + O2 -> O3

Dr.Air Industrial UV Equipment Technical Specifications Table

| Model | Flow rate (m³/h) | Dimensions (mm) | Power (W) | Number of UV bulbs | Flange |

| UV-5K | 5000 | 1350*1200*1160 | 2400 | 16 | Ø 300 |

| UV-10K | 10000 | 2350*1200*1270 | 4800 | 32 | Ø 500 |

| UV-15K | 15000 | 2350*1200*1570 | 6900 | 46 | Ø 700 |

| UV-20K | 20000 | 2900*1300*1870 | 9000 | 60 | Ø 650 |

| UV-30K | 30000 | 3800*1500*1900 | 13500 | 90 | Ø 750 |

| UV-40K | 40000 | 4100*1850*2200 | 16500 | 110 | Ø 850 |

| UV-50K | 50,000 | 4100*1850*2400 | 18000 | 120 | Ø 950 |

Outstanding advantages of industrial kitchen deodorizer with UV technology

Effective deodorization

With UV technology and the same side reaction of ozone, the kitchen deodorizer brings surprising cleaning efficiency. The efficiency of removing grease odors is up to 95%, gas odors, other flavors are also reduced to a high level.

Top substances removed include: Ammonia, Trimethylamine, Hydrogen Sulfide, Hydrogen Sulfide and Methyl Mercaptan, Dimethyl Disulfide, Carbon Disulfide and Styrene, Sulfide H2S, VOCs, Molecular chain structure of benzene, Toluene, Xylene, etc.

Smart & simple controller

Not only is it rated for its performance, the device also has a smart remote control. This allows users to easily adjust the operating mode.

High quality materials

In addition, industrial kitchen deodorizers are also highly safe as they are made of high-quality materials, with no possibility of UV leakage or risk of explosion. The product design is also simple, easy to install, easy to use and maintain.

Reviews

There are no reviews yet.