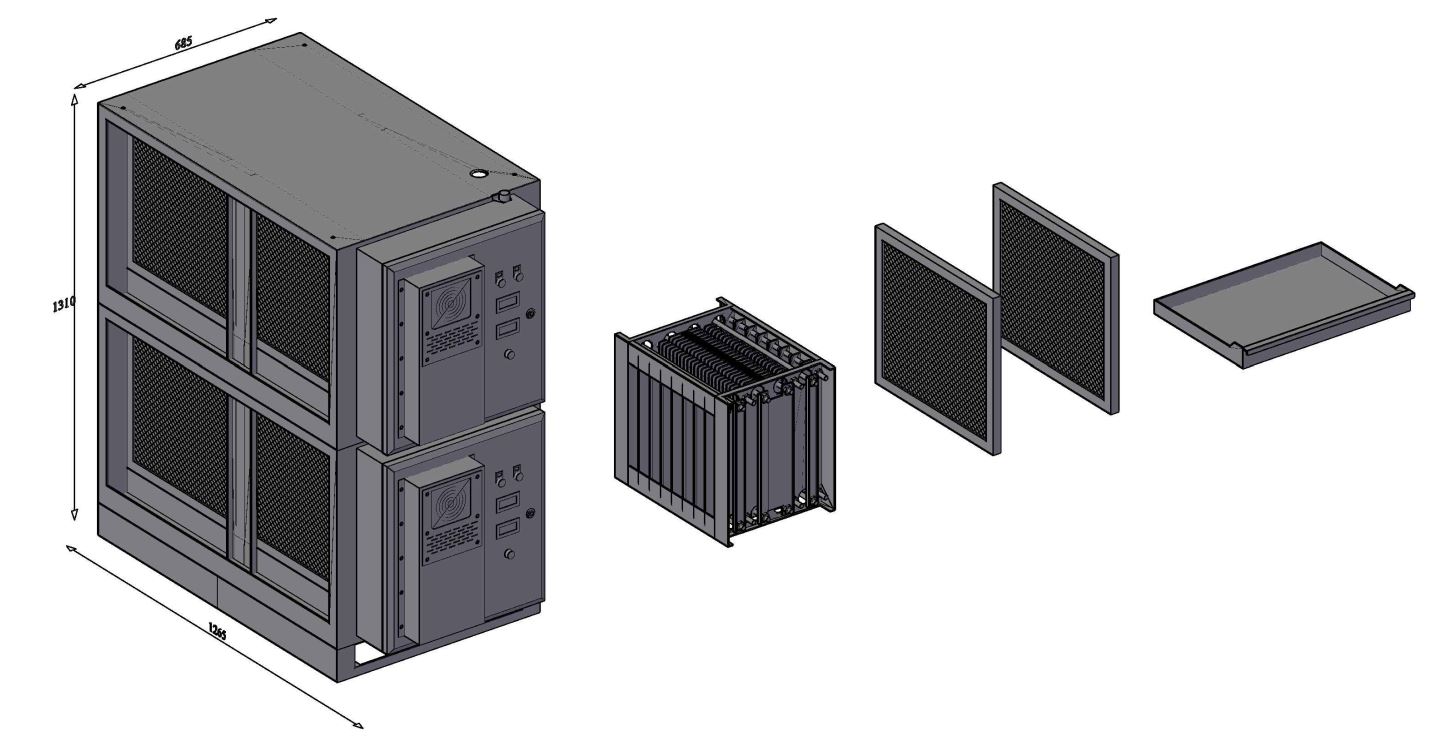

Dr.Air KT16000 industrial kitchen smoke electrostatic filter

- Model: Dr.Air KT16000

- Air flow: 16000m3/h

- Number of circuits: 2

- Circuit capacity: 600W

- Voltage: 220V

- Number of filters: 4

- External dimensions (LxWxH): 880x 1670x 710 mm

- Shooting size (WxH): 1360×500 mm

Kitchen exhaust gas mainly contains oil smoke particles generated during food processing and heating. During cooking, water droplets in vegetables evaporate and expand rapidly, some of which condense into mist. When combined with oil smoke, they form visible oil mist. Oil mist is mainly vapor, only a small amount of oil gas and oil smoke are not penetrated by water mist in the upper part. In addition, there are some unpleasant odors in the kitchen exhaust gas, making the air pollution more serious.

Thus, kitchen exhaust gas includes particulate matter and gaseous pollutants. The particle size of the particles is relatively small, usually less than 10 μm. The odor is mainly caused by gaseous pollutants.

To treat kitchen exhaust, it is important to capture most of the gaseous pollutants in the exhaust. With electrostatic filtration technology, the Dr.Air KT16000 machine helps remove up to 90% of pollutants in kitchen exhaust, returning clean air to the environment.

Outstanding advantages of KT16000 device

Compared with other exhaust gas treatment equipment on the market, Dr.Air KT16000 electrostatic filter has the following outstanding advantages:

- Clean exhaust gas with electrostatic filter technology with processing efficiency up to 90%. When exhaust gas is sucked in from the outside, passing through the ionized environment, dust particles are charged and become negative ions. According to physical properties, these particles are quickly attracted to the opposite electrode. As a result, dust sticks to the filter wall and cannot go out.

- Not only effectively cleans exhaust gas with electrostatic filtration technology, KT16000 also has a long service life and is environmentally friendly thanks to its stainless steel material. In addition to the machine shell, the internal filter is also made of this material, minimizing rust.

- Electrostatic filters can be reused many times by using high pressure water jet to remove dust layers on the filter wall.

- Simple control panel, easy to set up features

- There are 2 types: Dry electrostatic filter and wet electrostatic filter, meeting the maximum need to treat exhaust gas containing fine dust, grease particles, etc.

- Easy to combine with other devices in the processing system

Outstanding structural features

How to clean electrostatic filters

How to clean electrostatic filters

Cleaning the electrostatic filter is one of the indispensable processes in the process of using the Dr.Air KT16000 electrostatic filter to treat exhaust gas. Cleaning is carried out when the layers of dirt stick to the filter wall, so that the new dust particles after being charged are not affected.

To ensure the best results in cleaning the filter. After removing the filter from the KT16000, the user needs to soak it in a water tank and add a certain amount of chemicals. Under the impact of high-pressure water, dirt is removed, returning the shine to the filter. Finally, the user needs to use a dry cloth to dry and remove any remaining residue. Wait until the filter is completely dry and reinstall it in the system and use it as normal.

Reviews

There are no reviews yet.