Dr.Ozone D-2K Industrial Ozone Machine 2kg/h High Capacity Ozone Generator

74,906₫

- Model: Dr.Ozone D-2K

- Rated capacity: 2kg O3/h

- Power supply: 3800V/50Hz/3ph

- Rated power: 30-45kW

- Ozone adjustment: 10 – 100%

- Ozone concentration: 12 – 18mg/l

- Output pressure: 0.1Mpa

- Cooling flow: 2 – 4m3/h

- Oxygen supply: 100m3/h

What are the outstanding features and characteristics of Dr.Ozone D-2K industrial Ozone machine?

Dr.Ozone brand – HSVN Global is proud to be the ONLY UNIT in Vietnam that supply & produce industrial Ozone generators that have high capacity from 250g/h to 3kg O3/h. Dr.Ozone D-2K industrial ozone machine is one of which with a rated capacity of 2kg O3/h.

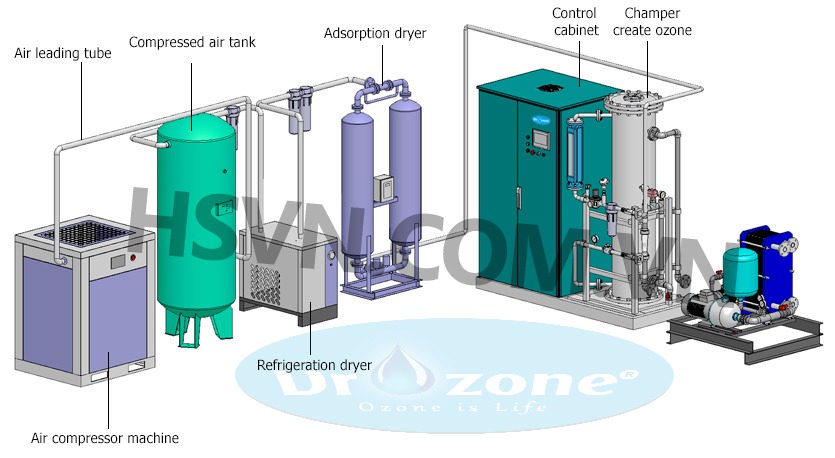

The large-capacity ozone machine needs to have the support of input air filtration systems. The systems include the air compressor, refrigeration dryer, adsorption dryer, unit increase oxygen concentration supply for ozone machine, system supply cooling water automatically to reduce the temperature of the ozone chamber.

The structure simulation of Dr.Ozone D-2K large capacity industrial ozone generator system

Specifications of Dr.Ozone D-2K High Capacity Ozone Generator

Machine create ozone

Adsorption air dryer

|

Pure oxygen supply system

Cold air dryer

|

|

The cooling water supply unit

|

||

Compressed air tank

|

The structure of Dr.Ozone D-2K industrial ozone machine

The Dr.Ozone high capacity ozone generator system has 2000g/h capacity and up owns a completely different structure compared to most ozone generators’ capacity under 250g/h. It includes the ozone creating machine and the system that supports to supply the large capacity and high-concentration pure oxygen (such as Air compressor, refrigeration dryer, adsorption machine, air filter & can be attached with ozone concentration measuring devices according to customer requirements).

The Parts’ Function Of Dr.Ozone D-2K Industrial Ozone Machine High Capacity System

- The air compressor of Dr.Ozone D-2K industrial ozone machine system is a screw air compressor, which helps the supply air flow get high pressure, constant, stable, low noise and low operating cost. The compressed air is then put into the compressed air chamber for storage, making the compressed air pressure stable, ensuring the necessary & sufficient conditions for the rear air filter system.

- Refrigeration dryers cool & condense compressed air, removing about 80% of the water present in the compressed air.

- The adsorption dryer consists of desiccant particles to dry the compressed air, removing all remaining water in the compressed air system. The process of hygroscopic & drying (granulation) is continuously repeated in the filter columns.

- Air filter: Filter removes oil, dust & impurities to ensure that the oil content of the gas entering the ozone chamber is less than 0.01mg/m3 and the particle size entering the ozone machine is less than 1 μm.

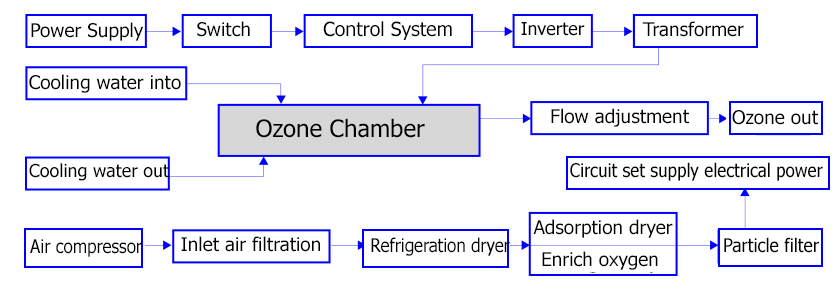

Before the air enters the chamber to create Ozone, it is decompressed by a pressure-reducing valve, the operation control system measures the flow of air entering the chamber, the pressure gauge, the thermometer displays the pressure & temperature of the outgoing air into the ozone launch chamber.

The most advanced Ozone machine line of Dr.Ozone D-2K is possible to integrate a real-time clock allowing the absolute exact setting of the machine’s operating time according to the cycle or integrate a PLC control system directly connected to the computer to control fastly and flexibly.

Honeycomb Ozone launch chamber

The machine creates ozone includes a device creates ozone also called a chamber launch ozone and circuit set supplies electrical power. Different from conventional ozone machines, the high-capacity ozone machine line includes a honeycomb-structured ozone launch tube system. The launch tubes use borosilicate glass dielectric tubes – a glass with a very low thermal expansion coefficient of silica and boron trioxide (~3 × 10−6 K−1 at 20 °C) that increased heat shock resistance.

Besides, the Ozone electrical cabinet is its indispensable part, which includes the transformer, inverter, frequency converter circuit, control circuits, etc. In addition, it also has other accessories including flow meter adjust air flow, valve reducing pressure, pressure gauge & valve adjusts thermograph.

Reviews

There are no reviews yet.